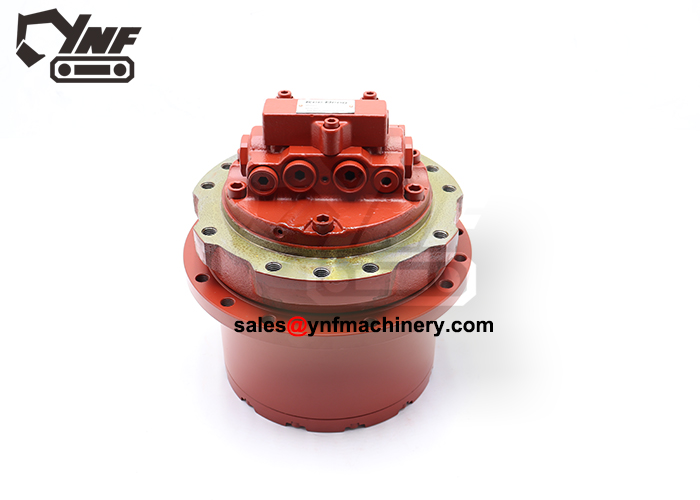

The Drive motor is the central component vital for an excavator’s operation. The drive motor comprises two types of machinery: a hydro motor and a gearbox. Both of these machinery components transfer driving force uniformly. The drive motor does this by slowing down revolutions of the drive wheels. This makes the excavator capable of steering through uneven terrains and lightens the workload on other excavator machine components. An issue in a drive motor or gearbox can lead to a breakdown of the excavator, which will cause a project delay, so keeping the excavator gearbox maintained is crucial for excavator efficiency. This blog will tell you about common drive motor issues and how to avoid them, so keep reading to learn more.

The Drive motor is the central component vital for an excavator’s operation. The drive motor comprises two types of machinery: a hydro motor and a gearbox. Both of these machinery components transfer driving force uniformly. The drive motor does this by slowing down revolutions of the drive wheels. This makes the excavator capable of steering through uneven terrains and lightens the workload on other excavator machine components. An issue in a drive motor or gearbox can lead to a breakdown of the excavator, which will cause a project delay, so keeping the excavator gearbox maintained is crucial for excavator efficiency. This blog will tell you about common drive motor issues and how to avoid them, so keep reading to learn more.

1. Oil Leakage from the Gearbox

Proper lubrication is vital for the seamless operation of the drive motor, and gear oil is essential for this. Without gear oil, the frictional forces can overheat the gears and cause unnecessary wear and tear. The source of the leakage is usually a damaged floating seal. To correct this malfunction, replacing the seal is recommended. Once that is accomplished, the gearbox will be restored to complete operational/

2. Excessively High Gearbox Oil Level

Too much oil in the gearbox is also not a good sign. During operation, the oil expands due to frictional heat generated by moving gears, which can displace the seals and build up pressure in the gearbox. So, make sure to avoid filling the gearbox to the brim.

If you have poured the correct amount of oil and the oil level is still high, the reason is a worn-out bearing or seal between the drive motor and gearbox. Replacing the seal will resolve this problem immediately.

3. Noisy Operation

Suppose you hear a lot of noise coming from the drive motor. In that case, this is an indication of internal malfunction that can damage the gearbox and result in expensive parts replacement. Three common issues are linked to high noise.

- Eroded Bearings or gears: Gears and seals wear out if not maintained properly, or they get eroded after reaching the end of their service life. When this happens, replacement of the drive motor is the only recommended fix.

- Oil Impurities: Overlooking regular maintenance can cause issues like metal swarf from improperly lubricated gears. This contaminates the oil and causes more friction in the components, which can erode them. To remedy this problem, the motor and gearbox need to be disassembled and cleaned and, if required, replaced with brand-new parts.

- Oil Level Too Low: If the oil level is low, a major reason is oil leakage and insufficient maintenance of the drive. If filling the oil does not solve the issue, fitting a new motor or gearbox is the way to go.

4. Struggle in Terrain Navigation

Gearbox and drive motor issues also negatively impact the excavator’s performance and make traversing harsh terrain difficult. The issue can be related to the following faults within the excavator.

- Lack of Power: Less power means that the excavator cannot climb an inclined surface. A major cause of this is low hydraulic pressure in the drive motor. To address this issue, first check the hydraulic fluid levels and assess them for leaks. If the leak cannot be located, contact a maintenance personnel or service center for additional help.

- Worn-Out Drive Motor: The most obvious case is an excessively old motor that has become eroded. In such cases, motor replacement is the only option.

- The gearbox is Eroded: When the gearbox is old and completely eroded, the only option is to replace it to restore the excavator’s efficiency.

- The motor is running, but the Gearbox is Not Functional: In a situation where the drive motor is operational but you cannot activate the gear, three components are the culprit.

- Motor shaft is broken: To resolve this, it is not sufficient to replace only the shaft; the first gear or sun gear also needs to be replaced. Fitting both new components will restore the functionality of the gearbox and motor.

- Damaged Drive Shaft: If the drive shaft is damaged or non-functional, replacing this component will address the issue. Once the drive shaft is replaced, the gearbox will be fully operational.

- Broken 1st gear: This is another common issue that renders the gearbox non-functional. In such a scenario, replacing the sun gear is the solution. Sun gear replacement will enable all gears to work correctly.

5. Motor Idling

An idling motor in the motor drive highlights a fault within the motor shaft or cylinder block. The motor shaft or cylinder block is likely broken, so replacing this component will fix the problem.

Conclusion

Most final drive problems arise from insufficient maintenance. Almost all significant failures can be avoided by consistently caring for your equipment and promptly addressing any issues. This proactive approach can significantly reduce the time and money needed for repairs, especially considering the high cost of replacing travel motors. By maintaining regular upkeep, you can ensure your final drive functions efficiently for its entire lifespan.