Komatsu excavator parts diagrams make repairs and maintenance straightforward. These diagrams label every component, helping you locate parts quickly. Their detailed visuals simplify complex machinery, even for those new to heavy equipment. You can describe parts accurately based on their location, reducing misunderstandings and speeding up repairs. This clarity minimizes errors and ensures your excavator operates efficiently. By using a komatsu excavator parts diagram, you save time and avoid costly mistakes, keeping your equipment in top condition.

Key Takeaways

Komatsu excavator parts diagrams help you find parts quickly.

These diagrams help you order the correct parts right away.

Learn how to read the diagram before starting any repairs.

Keep your maintenance log updated to track repairs easily.

Understanding Komatsu Excavator Parts Diagrams

What Are Komatsu Excavator Parts Diagrams?

Definition and purpose in excavator maintenance

A Komatsu excavator parts diagram is a detailed visual representation of the components in your excavator. It serves as a guide to help you identify, locate, and understand the various parts of your machine. These diagrams are essential for maintenance and repairs, ensuring you can quickly pinpoint the exact part you need. By using them, you reduce the risk of errors and keep your excavator running smoothly.

How they simplify complex machinery understanding

Excavators are intricate machines with numerous interconnected parts. A parts diagram simplifies this complexity by breaking down the machinery into manageable sections. You can see how each component fits together and functions within the system. This clarity makes it easier for you to understand your equipment, even if you’re new to operating or repairing heavy machinery.

Structure of Komatsu Excavator Parts Diagrams

Exploded views and part numbers

Komatsu excavator parts diagrams often use exploded views to display components. These views separate each part visually, showing how they connect without the clutter of overlapping pieces. Each part is assigned a unique number, making it easy for you to reference and order the correct component.

Key elements like labels and descriptions

Parts diagrams include several key elements that enhance their usability:

Element Type | Description |

|---|---|

Part Numbers | Unique identifiers for each component in the diagram. |

Descriptions | Detailed explanations of each part’s function and specifications. |

Quantities | The number of each part required for assembly or replacement. |

Component References | Specific references to the components for easier identification. |

These elements ensure you can quickly find the information you need, whether you’re replacing a part or performing routine maintenance.

Benefits of Using Komatsu Excavator Parts Diagrams

Time-saving and error-reducing advantages

Using a Komatsu excavator parts diagram saves you time during repairs. The clear layout helps you locate components faster, reducing the time spent searching for parts. It also minimizes misunderstandings when ordering replacements, ensuring you get the correct items the first time. This efficiency accelerates repairs and prevents unnecessary delays.

Enhanced accuracy in identifying and sourcing parts

The detailed schematics and meticulous labeling in these diagrams improve accuracy. You can identify parts with confidence and avoid confusion, even when dealing with similar components. This precision ensures you source the right parts, keeping your excavator in top condition. Additionally, the diagrams serve as a valuable training tool, helping you or your team learn about the machinery more effectively.

How to Locate Specific Parts Using Komatsu Excavator Parts Diagrams

Step-by-Step Guide to Finding Parts

Selecting the correct diagram for your Komatsu model

To locate specific parts, you must first select the correct diagram for your Komatsu excavator model. Each model has unique components, so using the wrong diagram can lead to confusion. Check your excavator’s manual or identification plate to confirm the model number. Once you have the correct model, access the corresponding parts diagram. Many diagrams are available online or through Komatsu’s official resources. Ensuring you use the right diagram saves time and prevents errors during repairs or maintenance.

Navigating the diagram to pinpoint the desired part

After selecting the correct diagram, focus on the section that corresponds to the area of your excavator requiring attention. For example, if you need to replace a hydraulic component, locate the hydraulic system section. Use the exploded views to identify the part’s position and its relationship to surrounding components. Pay attention to the part numbers and labels, as these provide essential details for ordering or replacing the part. This methodical approach ensures you find the exact part you need without unnecessary guesswork.

Using Part Numbers and Labels Effectively

Cross-referencing part numbers with inventory

Part numbers in the diagram are your best tool for sourcing components. Cross-reference these numbers with your inventory or supplier’s catalog to confirm availability. If you’re ordering from a supplier like YNF Machinery, provide the part number to ensure you receive the correct item. This step eliminates the risk of ordering incompatible parts, saving you time and money.

Avoiding confusion with similar components

Some parts may look similar but serve different functions. Carefully compare the part number and description in the diagram with the physical part. Double-check the specifications, such as size or material, to avoid mistakes. This attention to detail ensures you install the correct component, maintaining your excavator’s performance.

Troubleshooting Diagram-Related Issues

Handling missing or outdated diagrams

Missing or outdated diagrams can create challenges during repairs. These issues may lead to misconfigurations, wasted time, or even performance problems. To address this:

Keep updated records of your excavator’s parts and configurations.

Label components clearly for easier identification.

Regularly review and update your documentation to reflect changes.

These practices ensure you always have accurate information when you need it.

Tips for resolving unclear or ambiguous schematics

Sometimes, diagrams may include unclear labels or ambiguous details. When this happens:

Consult the manufacturer’s manual for additional context.

Reach out to experts or suppliers like YNF Machinery for guidance.

Use online forums or resources to clarify any uncertainties.

By taking these steps, you can resolve issues quickly and continue your repairs without unnecessary delays.

Using Komatsu Excavator Parts Diagrams for Repairs

Diagnosing Faulty Components

Identifying symptoms of part failure

Recognizing the symptoms of a faulty component is the first step in effective repairs. Pay attention to unusual noises, reduced performance, or visible wear and tear. For example, a hydraulic cylinder may show signs of leakage or reduced pressure, indicating a seal failure. Similarly, engine issues like excessive smoke or difficulty starting could point to problems with injectors or fuel pumps. Identifying these symptoms early helps you prevent further damage and costly repairs.

Leveraging diagrams to locate the affected part

Once you identify the symptoms, use the komatsu excavator parts diagram to locate the affected component. Focus on the section of the diagram that corresponds to the malfunctioning system, such as the engine or hydraulic system. The exploded views and part numbers make it easy to pinpoint the exact part. This approach ensures you address the root cause of the issue rather than just treating the symptoms.

Replacing Parts with Confidence

Steps for safe removal and installation

Replacing parts requires careful handling to avoid damage or injury. Begin by disconnecting power sources and relieving any pressure in hydraulic systems. Use the diagram to understand the part’s position and connections. Remove the faulty component using the appropriate tools, ensuring you don’t damage surrounding parts. When installing the replacement, follow the diagram to align it correctly and secure it in place. Test the system after installation to confirm proper functionality.

Ensuring compatibility with replacement parts, including YNF Machinery’s Excavator Engine Parts

Using compatible parts is crucial for successful repairs. Cross-reference the part number from the diagram with your supplier’s catalog. YNF Machinery offers high-quality excavator engine parts designed to meet or exceed OEM standards. These parts ensure durability and optimal performance, reducing the risk of future failures. By sourcing reliable components, you can complete repairs with confidence and maintain your excavator’s efficiency.

Avoiding Common Repair Pitfalls

Misidentifying parts during repairs

Misidentifying parts can lead to unnecessary expenses and extended downtime. To avoid this:

Double-check the part number and description in the diagram.

Compare the physical part with the diagram to confirm its identity.

Consult experts or suppliers if you’re unsure about a component.

This attention to detail ensures you replace the correct part and avoid treating symptoms instead of the root cause.

Skipping critical steps in the repair process

Skipping steps during repairs can compromise safety and equipment performance. For example, neglecting to relieve hydraulic pressure before replacing a seal can result in injuries. Always follow the diagram and repair guidelines step by step. Regular maintenance also prevents major malfunctions, extending your excavator’s lifespan and reducing repair costs.

Tip: Keep your komatsu excavator parts diagram accessible during repairs. It serves as a reliable guide, helping you avoid mistakes and complete tasks efficiently.

Using Komatsu Excavator Parts Diagrams for Maintenance

Planning Routine Maintenance

Identifying components requiring regular upkeep

Routine maintenance ensures your Komatsu excavator operates efficiently. Using a komatsu excavator parts diagram, you can identify components that need regular attention. Key areas include:

Engine: Perform oil and filter changes, inspect the fuel system, and monitor coolant levels.

Hydraulic System: Check fluid levels, inspect hoses for wear, and replace filters as needed.

Undercarriage: Clean and lubricate moving parts while inspecting for wear or damage.

Bucket: Examine for cracks, check the condition of the teeth, and repair or replace as necessary.

The maintenance manual also highlights critical tasks like scheduled fluid changes and regular inspections of hoses, cylinders, and valves. These steps help you catch potential issues early, preventing costly repairs.

Scheduling tasks using the diagram as a guide

A parts diagram simplifies scheduling by visually organizing components. Use it to plan maintenance tasks systematically. For example, group tasks by system, such as addressing all hydraulic components in one session. This approach saves time and ensures no part is overlooked. Regularly updating your schedule based on the diagram keeps your excavator in peak condition.

Performing Maintenance Tasks

Locating and accessing parts with ease

The diagram helps you locate parts quickly, reducing downtime. For instance, if you need to replace a hydraulic seal, the diagram shows its exact position and how it connects to other components. This clarity eliminates guesswork, allowing you to focus on the task.

Ensuring proper reassembly post-maintenance

After completing maintenance, reassemble parts carefully. Follow the diagram to ensure each component fits correctly. Misaligned parts can lead to performance issues or damage. Double-check connections and test the machine to confirm everything works as expected.

Preventative Maintenance Tips

Spotting wear and tear using diagrams

Parts diagrams help you identify wear and tear during inspections. Look for signs like cracks, leaks, or corrosion. For example, a worn hydraulic hose may appear frayed in the diagram, guiding you to replace it before it fails.

Keeping a maintenance log for future reference

Maintaining a detailed log enhances your ability to track performance and identify patterns. Logs help you schedule repairs proactively, reducing downtime. They also improve safety by ensuring routine inspections are completed. Accurate records make it easier to meet regulatory standards and pass audits.

Tip: Consistently updating your maintenance log extends your equipment’s lifespan and saves money by addressing minor issues early.

Tips for Maximizing the Use of Komatsu Excavator Parts Diagrams

Best Practices for Effective Use

Organizing and keeping diagrams accessible

Proper organization ensures you can quickly access your Komatsu excavator parts diagrams when needed. Store these diagrams in a climate-controlled environment to protect them from damage caused by humidity or extreme temperatures. A clean, dust-free storage area prevents wear and tear. Labeling and categorizing diagrams by machine model or system type further enhances accessibility. For frequently used diagrams, consider keeping digital copies on a tablet or computer for instant reference.

Each section of the excavator is meticulously labeled, providing a clear and straightforward reference that makes locating components a breeze. These diagrams serve as the perfect training resource, simplifying understanding and speeding up the learning process.

Familiarizing yourself with the layout before starting

Before beginning any repair or maintenance task, take time to study the diagram. Familiarize yourself with the layout, including the exploded views, part numbers, and labels. This preparation helps you navigate the diagram efficiently and reduces the chances of errors. Understanding how components connect will also make the repair process smoother and faster.

Common Mistakes to Avoid

Over-reliance on diagrams without consulting manuals

While diagrams are incredibly useful, relying solely on them can lead to mistakes. Always consult the manufacturer’s manual for additional details, such as torque specifications or safety precautions. The manual complements the diagram by providing step-by-step instructions and critical warnings.

Ignoring updates for newer models

Using outdated diagrams can cause confusion, especially if your excavator has undergone modifications or upgrades. Regularly check for updated diagrams that match your machine’s current configuration. Manufacturers often release revisions to reflect design changes or improvements.

Leveraging Additional Resources

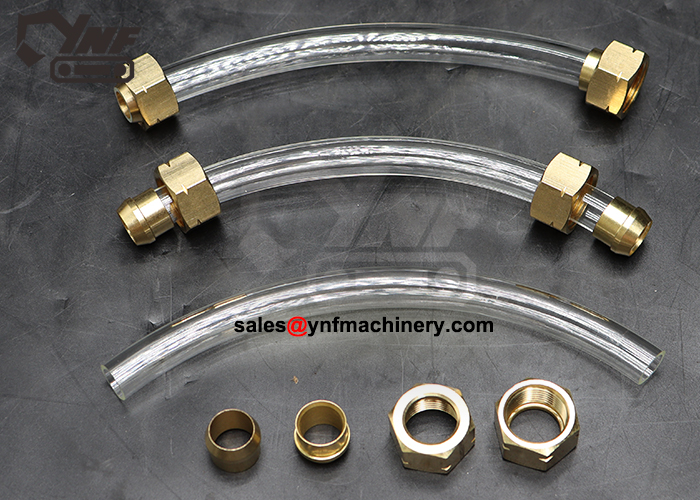

Using YNF Machinery’s Hydraulic Cylinder Seal Kits for maintenance

When maintaining hydraulic systems, high-quality components like YNF Machinery’s Hydraulic Cylinder Seal Kits ensure reliable performance. These kits prevent oil leaks and extend the lifespan of your excavator. Pairing these kits with your Komatsu excavator parts diagram simplifies the process of locating and replacing seals, saving you time and effort.

Consulting experts or online tools for complex issues

For complex repairs, don’t hesitate to seek help. Reach out to experts or suppliers like YNF Machinery for guidance. Online forums and resources can also provide valuable insights. Combining expert advice with your diagram ensures accurate and efficient repairs.

Komatsu excavator parts diagrams simplify repairs and maintenance, making them essential tools for operators. By using these diagrams, you can save time, reduce errors, and extend your equipment’s lifespan. Routine maintenance and proper operational procedures ensure your machinery performs efficiently and safely. Genuine parts, like those from YNF Machinery, further enhance performance and durability. High-quality components, such as Excavator Engine Parts and Hydraulic Cylinder Seal Kits, complement these diagrams, helping you maintain peak efficiency. Regular inspections and scheduled fluid changes prevent breakdowns, keeping your Komatsu machinery reliable and cost-effective.

FAQ

1. What is the best way to store Komatsu excavator parts diagrams?

Store diagrams in a clean, dry place to prevent damage. Use labeled folders or digital copies for easy access. Protect physical copies from moisture and dust. Digital versions can be saved on a computer or tablet for quick reference during repairs or maintenance.

2. How do you find the right parts diagram for your Komatsu model?

Check your excavator’s manual or identification plate for the model number. Use this number to locate the corresponding diagram online or through Komatsu’s official resources. Always verify the diagram matches your machine’s configuration to avoid confusion.

3. Can you use parts diagrams for training purposes?

Yes, parts diagrams are excellent training tools. They visually explain how components fit together and function. Studying these diagrams helps you or your team understand the machinery better, making repairs and maintenance more efficient.

4. What should you do if a diagram is unclear or outdated?

Consult the manufacturer’s manual for additional details. Contact experts or suppliers like YNF Machinery for guidance. Online forums can also provide helpful insights. Always update your diagrams to match your machine’s current configuration.

5. Why are part numbers important when using diagrams?

Part numbers ensure you order the correct components. Cross-reference these numbers with your inventory or supplier’s catalog. This step eliminates errors, saves time, and guarantees compatibility, keeping your excavator in top condition.

Tip: Always double-check part numbers before placing an order to avoid unnecessary delays.