Wear parts for excavators are vital components that endure constant stress during operation. These parts, such as bucket teeth and hydraulic seals, face significant wear and tear due to heavy-duty tasks. Their condition directly impacts the efficiency and safety of your excavator. Regular maintenance and timely replacement of these parts prevent unexpected breakdowns and costly repairs. By ensuring these components remain in optimal condition, you can extend the lifespan of your equipment and maintain peak performance in demanding environments.

Key Takeaways

Regularly inspect wear parts like bucket teeth and hydraulic seals to identify signs of wear early, preventing costly repairs and downtime.

Maintain optimal performance by keeping wear parts clean and lubricated, which reduces friction and extends their lifespan.

Replace worn parts promptly to ensure your excavator operates efficiently and safely, minimizing the risk of unexpected breakdowns.

Utilize high-quality replacement parts from trusted suppliers like YNF Machinery to enhance durability and reliability in demanding conditions.

Adopt proper operation techniques to minimize wear on components, ensuring smoother performance and reducing maintenance costs.

Conduct daily inspections and follow a preventive maintenance schedule to keep your excavator in peak condition and maximize productivity.

What Are Wear Parts for Excavators?

Definition and Importance

Wear parts for excavators are components that endure constant friction, impact, and pressure during operation. These parts include bucket teeth, cutting edges, side wear plates, and undercarriage components. They are designed to handle the intense demands of heavy-duty tasks, such as digging, lifting, and moving materials. Over time, these parts wear down due to continuous use, requiring regular inspection and replacement.

The importance of wear parts lies in their role in maintaining the efficiency and safety of your excavator. Worn-out parts can reduce the machine’s performance, increase fuel consumption, and even lead to unexpected breakdowns. For example, damaged bucket teeth can make digging less effective, while worn tracks can compromise stability. By keeping these parts in good condition, you ensure that your excavator operates at its best, even in challenging environments.

“Excavator attachments, such as bucket teeth, cutting edges, and wear plates, are subject to wear during operation. These parts should be regularly inspected and replaced as needed, based on wear levels or manufacturer guidelines.” — Excavator Maintenance Expert

How Wear Parts Contribute to Excavator Performance

Wear parts play a crucial role in the overall performance of your excavator. Each part is designed to perform a specific function that directly impacts the machine’s efficiency. For instance:

Bucket Teeth: These sharp, durable components enhance digging efficiency by breaking through tough materials like soil, rock, and gravel. High-quality bucket teeth reduce the effort required by the machine, saving energy and time.

Cutting Edges: These edges improve the precision and smoothness of material handling. They also protect the bucket from excessive wear, extending its lifespan.

Side Wear Plates: These plates shield the sides of the bucket from abrasion and impact, ensuring durability during heavy-duty operations.

Undercarriage Components: Tracks, rollers, and sprockets provide stability and mobility. They distribute the machine’s weight evenly, allowing it to move smoothly across various terrains.

By ensuring that these wear parts remain in optimal condition, you can maximize your excavator’s productivity. Regular maintenance and timely replacement prevent excessive wear on other excavator parts, reducing the risk of costly repairs. Additionally, well-maintained wear parts contribute to safer operations, minimizing the chances of accidents caused by equipment failure.

Essential Wear Parts for Excavators and Their Functions

Bucket Wear Parts

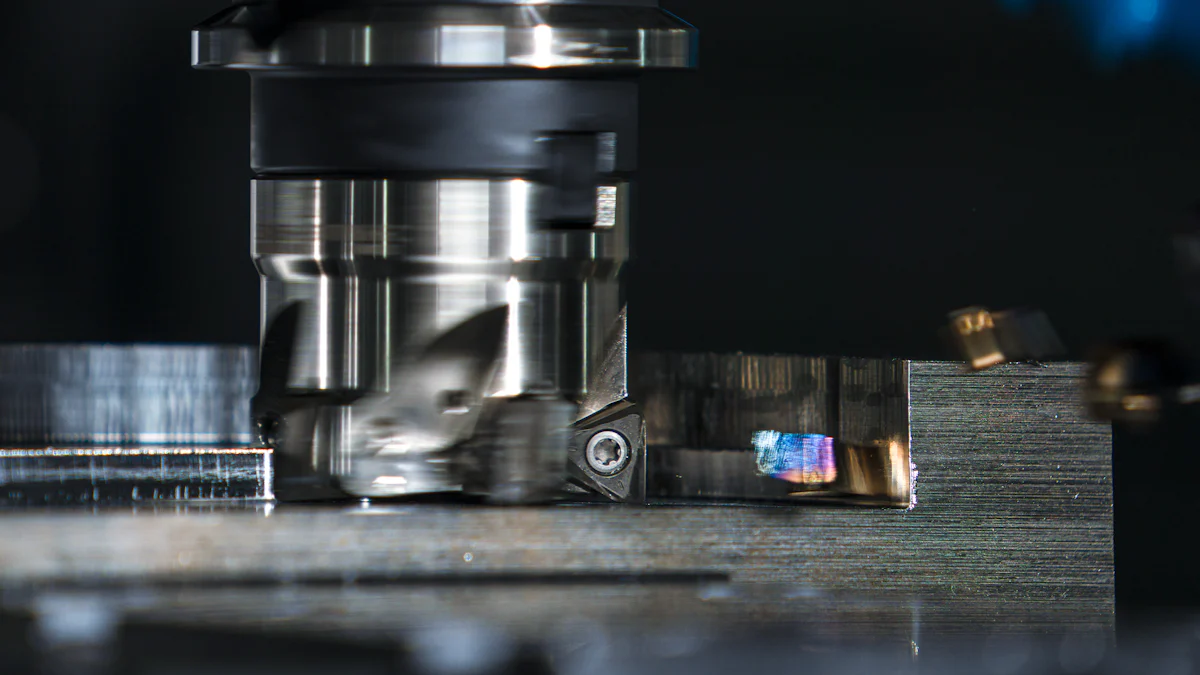

Bucket Teeth: Purpose and Materials

Bucket teeth are among the most vital bucket wear parts. These sharp, durable components attach to the bucket’s edge, enabling your excavator to dig through tough materials like soil, rock, and gravel. They enhance digging efficiency by reducing the effort required from the machine. High-quality bucket teeth are typically made from materials like high-strength steel or tungsten carbide, ensuring they withstand abrasive conditions. Regular inspection is essential to identify wear or damage. Replacing worn bucket teeth promptly prevents reduced performance and protects other excavator parts from unnecessary strain.

“Excavator attachments, such as bucket teeth, cutting edges, and wear plates, are subject to wear during operation. These parts should be regularly inspected and replaced as needed, based on wear levels or manufacturer guidelines.” — Excavator Maintenance Guide

Side Wear Plates: Protection and Durability

Side wear plates shield the sides of the bucket from abrasion and impact during heavy-duty operations. These plates are crucial for maintaining the bucket’s structural integrity and extending its lifespan. Made from wear-resistant materials, they provide durability even in the harshest environments. By protecting the bucket from excessive wear, side wear plates reduce the need for frequent repairs or replacements. Regular maintenance ensures these plates remain effective, allowing your excavator to perform efficiently.

Cutting Edges: Types and Applications

Cutting edges are essential bucket wear parts that improve material handling precision. They attach to the bottom edge of the bucket, providing a smooth and clean cut through materials. Cutting edges come in various types, including straight, serrated, and reversible designs, each suited for specific applications. For instance, straight edges work well for general digging, while serrated edges excel in cutting through compacted soil or frozen ground. Reversible cutting edges offer extended usability by allowing you to flip them when one side wears out. Maintaining sharp and intact cutting edges ensures optimal performance and reduces wear on the bucket.

Undercarriage Wear Parts

Tracks: Mobility and Stability

Tracks are critical undercarriage components that provide mobility and stability to your excavator. They distribute the machine’s weight evenly, allowing it to traverse various terrains with ease. Tracks endure constant friction and pressure, making them prone to wear over time. Regular inspection helps identify issues like cracks or uneven wear. Replacing damaged tracks promptly ensures smooth movement and prevents further damage to other undercarriage parts.

Rollers, Idlers, and Sprockets: Supporting Excavator Movement

Rollers, idlers, and sprockets are common excavator components within the undercarriage system. Rollers support the tracks, ensuring they stay aligned during operation. Idlers maintain track tension, preventing slippage and enhancing stability. Sprockets drive the tracks, enabling the excavator to move efficiently. These parts work together to support the machine’s movement and stability. Regular maintenance, including cleaning and lubrication, extends their lifespan and ensures reliable performance.

Hydraulic System Wear Parts

Hoses and Seals: Ensuring Hydraulic Efficiency

Hoses and seals are vital hydraulic system wear parts that ensure efficient power transmission. Hydraulic hoses transport fluid under high pressure, while seals prevent leaks and maintain system integrity. Over time, these components can degrade due to heat, pressure, and environmental factors. Inspecting hoses for cracks or leaks and replacing worn seals promptly prevents hydraulic inefficiency and potential system failure. Keeping these parts in good condition ensures your excavator operates smoothly.

Pins and Bushings: Reducing Friction and Wear

Pins and bushings play a crucial role in reducing friction between moving parts. These components connect various excavator parts, such as the bucket and arm, allowing smooth and controlled movement. Constant use can cause pins and bushings to wear down, leading to increased friction and reduced efficiency. Regular lubrication minimizes wear, while timely replacement prevents further damage to connected components. Maintaining these parts ensures your excavator performs reliably in demanding tasks.

Specialized Wear Parts from YNF Machinery

Excavator Couplings: Enhancing Power Transmission

excavator couplings are essential components that ensure efficient power transmission between the engine and the hydraulic pump system.

YNF Machinery offers a wide range of excavator couplings designed to meet the rigorous demands of heavy machinery. Crafted from high-quality materials, these couplings are built to withstand harsh working conditions. Their robust construction minimizes wear and tear, reducing the risk of unexpected breakdowns. Additionally, their easy installation and maintenance save you valuable time and effort.

Key benefits of YNF Machinery’s excavator couplings include:

Durability: Engineered to endure extreme conditions, ensuring long-lasting performance.

Flexibility: Designed to compensate for misalignment and axial displacement, enhancing operational efficiency.

Versatility: Available in various types, such as Centaflex-A, Centaflex-H, and Bowex, to suit different excavator models and applications.

By choosing YNF Machinery’s excavator couplings, you can enhance your machine’s reliability and productivity. Regular inspection and timely replacement of worn couplings ensure uninterrupted power transmission, keeping your excavator in peak condition.

“Efficient power transmission is critical for excavator performance. High-quality couplings reduce downtime and improve overall machinery reliability.” — Excavator Maintenance Guide

CF-A Couplings: Vibration Damping and Misalignment Compensation

The CF-A Couplings from YNF Machinery are specifically designed to address two critical challenges in heavy machinery: vibration damping and misalignment compensation. These couplings ensure smooth torque transmission between shafts, even under demanding conditions. Their advanced design reduces vibrations, protecting your excavator’s components from excessive wear and tear.

Made from SVR 3L hybrid rubber, CF-A couplings offer exceptional elasticity and wear resistance. This material combines the best properties of natural and synthetic rubber, ensuring durability and long-term performance. The couplings also feature a Shore hardness of 60 to 65 degrees, providing the perfect balance between flexibility and strength.

Key features of CF-A couplings include:

Vibration Damping: Minimizes noise and protects machinery from damage caused by excessive vibrations.

Misalignment Compensation: Accommodates radial, angular, and axial misalignments, ensuring smooth operation.

Overload Protection: Designed to withstand overload conditions, preventing catastrophic failures.

CF-A couplings are compatible with Centaflex-A couplings, making them a cost-effective and versatile solution for your excavator. Their ability to handle high torque and challenging conditions makes them an ideal choice for industries like construction, mining, and infrastructure development.

“CF-A couplings provide superior vibration damping and misalignment compensation, ensuring reliable performance in heavy-duty applications.” — YNF Machinery Product Expert

By incorporating YNF Machinery’s CF-A couplings into your excavator, you can enhance its efficiency and longevity. Regular maintenance and proper installation of these couplings ensure optimal performance, reducing downtime and maintenance costs.

How to Identify Signs of Wear on Excavator Parts

Recognizing wear on your excavator parts is essential for maintaining optimal performance and avoiding costly downtime. By identifying early signs of wear, you can take proactive measures to replace or repair components before they fail.

Visual Inspection Techniques

Cracks, Deformation, and Thinning

Inspecting your excavator parts visually is one of the simplest yet most effective ways to detect wear. Look for cracks, which often appear on high-stress components like bucket teeth, cutting edges, or hydraulic hoses. These cracks can compromise the structural integrity of the part, leading to sudden failures during operation.

Deformation is another common sign of wear. For example, bent or warped side wear plates can indicate excessive stress or improper usage. Thinning, especially on cutting edges or tracks, suggests that the material has worn down significantly due to friction and abrasion. Regularly checking for these signs ensures that you address issues before they escalate.

Uneven Wear Patterns

Uneven wear patterns often reveal underlying problems with alignment or improper usage. For instance, tracks with uneven wear may indicate misaligned rollers or sprockets. Similarly, bucket teeth that wear down unevenly could suggest incorrect digging angles or excessive force during operation. Identifying these patterns helps you pinpoint the root cause and take corrective action to prevent further damage.

“Uneven wear on excavator parts often signals alignment issues or improper operation. Addressing these problems early can save you from costly repairs.” — Excavator Maintenance Specialist

Performance Indicators

Reduced Efficiency in Digging or Movement

A noticeable drop in your excavator’s efficiency often points to worn parts. If your machine struggles to dig through materials or moves slower than usual, it may be time to inspect components like bucket teeth, cutting edges, or tracks. Worn parts require more effort from the machine, increasing fuel consumption and reducing overall productivity.

Increased Vibrations or Fuel Consumption

Excessive vibrations during operation can indicate worn pins, bushings, or couplings. These vibrations not only affect the operator’s comfort but also accelerate wear on other parts of the excavator. Additionally, higher fuel consumption often results from worn components that force the machine to work harder. Monitoring these performance indicators allows you to address wear issues promptly, ensuring smooth and efficient operation.

“Increased vibrations and fuel consumption are clear signs of wear on excavator parts. Regular maintenance can help you avoid these issues and keep your machine running efficiently.” — YNF Machinery Product Expert

By combining visual inspections with performance monitoring, you can effectively recognize wear on your excavator parts. This proactive approach minimizes downtime, extends the lifespan of your equipment, and ensures consistent performance in demanding environments.

Maintenance Tips to Extend the Lifespan of Wear Parts

Regular Cleaning and Lubrication

Keeping your excavator’s wear parts clean ensures optimal performance and longevity. Dirt, debris, and grime can accumulate on components like bucket teeth, tracks, and hydraulic hoses. These materials increase friction and accelerate wear. Cleaning these parts after each use prevents buildup and reduces unnecessary strain on your machine.

Lubrication is equally important. Moving parts, such as pins and bushings, require proper lubrication to minimize friction and prevent overheating. Use high-quality lubricants recommended by the manufacturer. Apply them regularly to ensure smooth operation and reduce wear. Neglecting lubrication can lead to premature failure of critical components.

Regular cleaning and lubrication are essential for maintaining the efficiency and durability of excavator wear parts. — Excavator Maintenance Specialist

Scheduled Inspections and Preventive Maintenance

Daily inspections help you identify potential issues before they escalate. Walk around your excavator and check high-risk areas like bucket teeth, sprockets, rollers, and tracks. Look for visible signs of wear, such as cracks, thinning, or deformation. Addressing these problems early prevents costly repairs and downtime.

Preventive maintenance involves following a consistent schedule for servicing your excavator. Replace worn parts before they fail. For example, inspect hydraulic hoses for leaks and replace damaged seals promptly. Keep track of maintenance intervals recommended by the manufacturer. This proactive approach ensures your machine operates efficiently and safely.

“A daily walk-around inspection can save you from unexpected breakdowns and extend the life of your equipment.” — Excavator Maintenance Guide

Proper Operation Techniques to Minimize Wear

How you operate your excavator significantly impacts the lifespan of its wear parts. Avoid excessive force when digging or lifting heavy loads. Overloading the bucket or using improper angles can cause uneven wear on bucket teeth and cutting edges. Operate the machine smoothly to reduce stress on components.

Pay attention to terrain. Driving over rough or uneven surfaces can damage tracks and undercarriage parts. Use appropriate speed and avoid sudden stops or turns. Proper operation reduces unnecessary strain on your excavator and helps maintain its performance.

“Adopting correct operating techniques not only improves efficiency but also minimizes wear on critical components.” — Excavator Operator Training Manual

By incorporating these maintenance practices into your routine, you can extend the lifespan of your excavator’s wear parts. Regular cleaning, timely inspections, and proper operation ensure your machine remains reliable and productive in demanding environments.

Using High-Quality Replacement Parts from YNF Machinery

High-quality replacement parts play a crucial role in maintaining your excavator’s performance and durability.

Why Choose YNF Machinery Replacement Parts?

YNF Machinery specializes in manufacturing excavator parts that deliver exceptional performance and reliability. Their products undergo strict quality inspections to ensure they meet industry standards. By using YNF Machinery parts, you gain several advantages:

Durability: YNF Machinery parts are crafted from high-strength materials, ensuring they withstand harsh working conditions.

Compatibility: The parts are designed to fit a wide range of excavator models, making them a versatile choice for your equipment.

Cost-Effectiveness: High-quality parts reduce the frequency of replacements, saving you money in the long run.

“Investing in high-quality replacement parts minimizes downtime and enhances the efficiency of your excavator.” — Excavator Maintenance Expert

Key Features of YNF Machinery Parts

YNF Machinery offers a variety of replacement parts, including bucket teeth, hydraulic couplings, and undercarriage components. Each part is engineered to provide optimal performance. For example:

Bucket Teeth: Made from wear-resistant materials, these teeth improve digging efficiency and reduce strain on your machine.

Hydraulic Couplings: Designed for smooth power transmission, these couplings enhance the reliability of your hydraulic system.

Tracks and Rollers: Built to endure constant friction, these components ensure stability and mobility across challenging terrains.

How YNF Machinery Parts Enhance Your Excavator

Using YNF Machinery replacement parts ensures your excavator operates at peak efficiency. These parts minimize wear on other components, reducing the likelihood of costly repairs. For instance:

Replacing worn bucket teeth with durable YNF Machinery teeth improves digging precision and reduces fuel consumption.

Installing high-quality hydraulic couplings prevents leaks and maintains consistent power transmission.

Upgrading to robust tracks and rollers enhances your excavator’s stability, even on uneven surfaces.

Proactive Maintenance with YNF Machinery Parts

Daily inspections help you identify worn parts before they cause major issues. Pay close attention to high-risk areas like bucket teeth, sprockets, and tracks. Replace damaged components promptly with YNF Machinery parts to avoid further damage. Regular maintenance, combined with high-quality replacements, keeps your excavator running smoothly.

“Conducting daily checks and using reliable replacement parts ensures your excavator remains productive and efficient.” — Excavator Maintenance Guide

By choosing YNF Machinery for your replacement parts, you invest in the long-term performance and reliability of your excavator. Their commitment to quality and customer satisfaction makes them a trusted partner for all your heavy machinery needs.

When and How to Replace Wear Parts

Determining the Right Time for Replacement

Knowing when to replace wear parts is essential for maintaining your excavator’s performance and avoiding costly downtime. Regular inspections help you identify signs of wear before they escalate into major issues. Look for visible damage, such as cracks, thinning, or deformation, on components like bucket teeth, cutting edges, and tracks. Uneven wear patterns often indicate alignment problems or improper usage, which require immediate attention.

If your excavator struggles with digging, lifting, or moving materials, worn parts may be the cause.

“Timely replacement of worn parts prevents unexpected breakdowns and extends the lifespan of your equipment.” — Excavator Maintenance Specialist

Steps for Replacing Common Wear Parts

Replacing wear parts requires careful planning and execution to ensure your excavator remains in optimal condition. Follow these steps for a smooth replacement process:

Identify the Worn Part Conduct a thorough inspection to pinpoint the specific part that needs replacement. Check for visible damage, performance issues, or unusual noises during operation.

Gather the Necessary Tools and Parts Obtain high-quality replacement parts from trusted suppliers like YNF Machinery. Ensure you have the required tools, such as wrenches, hammers, or hydraulic presses, for the replacement process.

Prepare the Excavator Park the machine on a flat, stable surface. Turn off the engine and release any hydraulic pressure to ensure safety during the replacement.

Remove the Worn Part Follow the manufacturer’s guidelines to detach the damaged component. For example, use a pin removal tool to extract worn bucket teeth or a track tensioner to loosen tracks.

Install the New Part Align the replacement part correctly and secure it using bolts, pins, or other fasteners. Ensure proper fitment to avoid misalignment or operational issues.

Test the Machine Start the excavator and perform a test run to check for smooth operation. Monitor for any unusual sounds or vibrations that may indicate improper installation.

By following these steps, you can replace wear parts efficiently and minimize downtime. Regular maintenance and timely replacements keep your excavator running at peak performance.

Benefits of Professional Assistance for Complex Replacements

Some wear parts, such as hydraulic couplings or undercarriage components, require specialized knowledge and tools for replacement. Seeking professional assistance ensures these complex tasks are handled correctly. Trained technicians have the expertise to diagnose issues accurately and perform replacements without causing further damage.

Professional services also save you time and effort. Technicians work efficiently, reducing downtime and allowing you to resume operations quickly. Additionally, they use high-quality parts and follow industry standards, ensuring your excavator remains reliable and safe.

“Professional assistance for complex replacements guarantees precision and enhances the longevity of your equipment.” — YNF Machinery Product Expert

Investing in expert help for challenging replacements protects your excavator from potential risks. It also ensures that all components function harmoniously, maximizing productivity and extending the machine’s lifespan.

Benefits of Proper Wear Part Maintenance

Enhanced Excavator Performance and Efficiency

Proper maintenance of wear parts directly impacts the efficiency and productivity of your excavator.

“High-quality wear parts, combined with regular maintenance, ensure your excavator delivers peak performance even in demanding conditions.” — Excavator Maintenance Specialist

Reduced Downtime and Repair Costs

Additionally, using durable wear parts from trusted suppliers like YNF Machinery ensures fewer replacements, saving you money in the long run.

“Investing in durable wear parts reduces operational costs and keeps your equipment running without interruptions.” — YNF Machinery Product Expert

Increased Equipment Longevity with YNF Machinery Parts

Maintaining wear parts not only improves performance but also extends the lifespan of your excavator. Components like cutting edges, side wear plates, and hydraulic couplings endure constant stress during operation. High-quality replacements from YNF Machinery are designed to withstand harsh conditions, ensuring durability and reliability. For example, their excavator couplings and hydraulic seals are crafted from premium materials, offering superior resistance to wear and tear. By choosing such parts, you protect your equipment from premature failure and maximize its operational life.

“Durable wear parts from YNF Machinery enhance the longevity of your excavator, ensuring reliable performance across various terrains.” — Excavator Maintenance Guide

Regular maintenance, combined with high-quality replacements, ensures your excavator remains efficient, reliable, and cost-effective. By prioritizing wear part care, you not only improve daily operations but also secure long-term savings for your business.

Wear parts are essential for maintaining your excavator’s performance and safety. Regular inspections and timely replacements ensure your machine operates efficiently, reducing the risk of costly breakdowns. By adopting a proactive maintenance routine, you can extend the lifespan of critical components and enhance overall productivity. Choosing high-quality wear parts, like those from YNF Machinery, guarantees durability and reliability in demanding conditions. Trust YNF Machinery as your partner for premium excavator parts, ensuring your equipment remains dependable and efficient for years to come.

FAQ

What are wear parts for excavators?

Wear parts are components on your excavator that experience constant friction, impact, or pressure during operation. These include bucket teeth, cutting edges, side wear plates, tracks, and hydraulic seals. They are designed to handle heavy-duty tasks but require regular inspection and replacement due to wear and tear.

“Wear parts are essential for maintaining the efficiency and safety of your excavator. Regular maintenance ensures they perform optimally.” — Excavator Maintenance Specialist

How often should I inspect wear parts?

You should inspect wear parts daily or before each use.

How can I extend the lifespan of wear parts?

You can extend the lifespan of wear parts by following these practices:

Clean parts regularly to remove dirt and debris.

Lubricate moving components like pins and bushings.

Monitor wear patterns and replace parts when necessary.

Operate the excavator smoothly to reduce stress on components.

“Regular maintenance, such as keeping GETs sharp and monitoring wear patterns, is key to extending their lifespan.” — Excavator Maintenance Guide

When should I replace bucket teeth?

Replace bucket teeth when they show significant wear, such as thinning, cracks, or reduced digging efficiency. Worn teeth can strain your excavator and reduce productivity. Regularly inspect them and replace them promptly to maintain optimal performance.

What are the benefits of using high-quality replacement parts?

High-quality replacement parts offer durability, reliability, and compatibility with your excavator.

How do I know if my tracks need replacement?

Inspect your tracks for cracks, uneven wear, or thinning. If your excavator struggles with movement or stability, it may indicate worn tracks. Replacing them promptly prevents further damage to undercarriage components like rollers and sprockets.

Why is lubrication important for wear parts?

Lubrication minimizes friction between moving parts, such as pins and bushings. It prevents overheating and reduces wear, ensuring smooth operation. Use high-quality lubricants and apply them regularly to keep your excavator running efficiently.

Can I replace wear parts myself, or should I hire a professional?

You can replace simple wear parts, like bucket teeth or cutting edges, by following the manufacturer’s guidelines. For complex components, such as hydraulic couplings or undercarriage parts, hiring a professional ensures proper installation and avoids potential risks.

“Professional assistance for complex replacements guarantees precision and enhances the longevity of your equipment.” — YNF Machinery Product Expert

How do I choose the right replacement parts for my excavator?

Choose replacement parts based on your excavator’s model and specifications. Look for durable materials and compatibility with your machine. Trusted suppliers like YNF Machinery offer a wide range of high-quality parts designed to meet industry standards.

What happens if I neglect wear part maintenance?

Neglecting wear part maintenance can lead to unexpected breakdowns, increased fuel consumption, and costly repairs. Worn parts can also compromise safety and reduce your excavator’s efficiency. Regular inspections and timely replacements prevent these issues and keep your machine in peak condition.

“Timely replacement of worn parts prevents unexpected breakdowns and extends the lifespan of your equipment.” — Excavator Maintenance Specialist