Choosing the right Yanmar mini excavator parts for your equipment is essential to keep it running smoothly and efficiently. The importance of quality excavator parts cannot be overstated, as using low-quality or incompatible components can lead to costly repairs and downtime. Specific Yanmar mini excavator parts, like hydraulic systems or undercarriage components, directly impact their functionality and performance. YNF Machinery, with its commitment to providing top-notch parts, ensures you get the best mini excavator experience. Their expertise makes maintenance accessibility easier, helping you choose the right excavator parts for your Yanmar mini excavator model.

Key Takeaways

Ensure compatibility by verifying your Yanmar mini excavator model number and part codes before purchasing parts.

Invest in high-quality parts to enhance the efficiency and lifespan of your excavator, reducing the need for frequent replacements.

Consider the long-term value of parts; genuine components may have a higher upfront cost but often save money over time through improved performance.

Choose a reliable supplier for expert guidance, a wide selection of parts, and competitive pricing.

Regularly inspect and maintain your excavator to catch potential issues early and ensure optimal performance.

Understand the differences between genuine and aftermarket parts to make informed decisions that suit your budget and needs.

Utilize expert support from suppliers to simplify the parts selection process and enhance your excavator’s operational efficiency.

Key Factors to Consider When Choosing Yanmar Mini Excavator Parts

When it comes to maintaining your compact excavators, making the right selection of parts is crucial. The wrong choice can lead to inefficiency, costly repairs, and downtime. Let’s dive into the key considerations when choosing parts for your Yanmar mini excavator.

Compatibility with Your Excavator Model

Ensuring compatibility is the first step in selecting the right parts. Every Yanmar mini excavator model has unique specifications, so you need to match the parts precisely. For instance, models like B10, VIO10, and SV08 require specific components to function optimally. Using incompatible parts can cause operational issues or even damage your equipment.

To avoid this, always verify the model number and part codes of your excavator. Consult the user manual or seek guidance from experts. Trusted suppliers like YNF Machinery provide detailed information to help you identify the right parts for your machine. Their wide selection of parts ensures you’ll find what you need for various Yanmar models.

Quality and Durability of Mini Excavator Parts

The quality of the parts you choose directly impacts the efficiency and lifespan of your excavator. High-quality parts are designed to withstand tough working conditions, ensuring your machine operates smoothly. For example, YNF Machinery offers durable components like hydraulic systems and undercarriage parts that enhance performance.

Low-quality parts may seem like a cost-saving option, but they often lead to frequent replacements and reduced efficiency. Investing in reliable, high-quality parts minimizes downtime and keeps your compact excavator running at its best.

Cost-Effectiveness and Long-Term Value

While upfront costs matter, you should also consider the long-term value of the parts. Genuine or high-grade aftermarket parts may have a higher initial price, but they often last longer and perform better. This reduces the need for frequent replacements, saving you money over time.

Think about how the parts contribute to the overall efficiency of your compact excavator. Reliable parts not only improve performance but also reduce fuel consumption and maintenance costs. Suppliers like YNF Machinery offer competitive pricing and access to a wide selection of parts, making it easier to balance quality and affordability.

By focusing on compatibility, quality, and cost-effectiveness, you can ensure your Yanmar mini excavator delivers optimal performance. Whether you’re tackling construction projects or wondering when to use a mini excavator, the right parts make all the difference.

Supplier Reliability and Support (e.g., YNF Machinery)

Choosing the right supplier plays a huge role in ensuring your Yanmar mini excavator operates at its best. A reliable supplier doesn’t just sell parts; they provide you with the confidence that your equipment will stay in top shape. So, what should you look for in a supplier?

1. Proven Track Record

A trustworthy supplier has a history of delivering quality products and excellent service. For over 35 years, YNF Machinery has built a solid reputation in the excavator parts industry. Their experience ensures you get parts that meet high standards and perform reliably. When you choose a supplier with a proven track record, you reduce the risk of receiving subpar components.

2. Wide Range of Parts

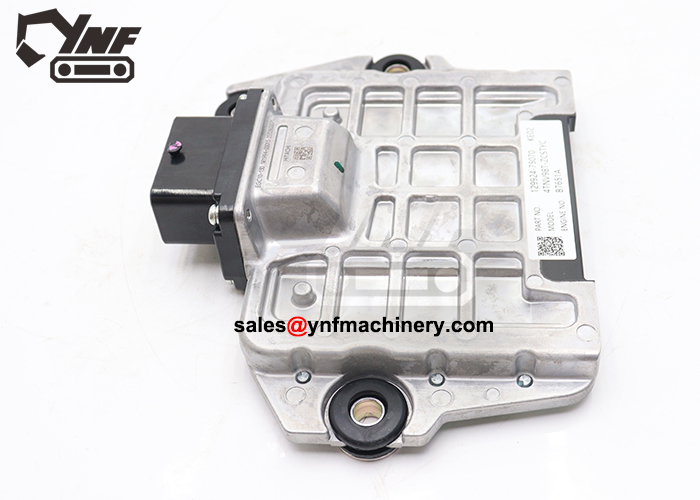

You need access to a variety of parts to maintain your excavator effectively. YNF Machinery offers a comprehensive selection of Yanmar mini excavator parts, including components for models like B10, VIO10, and SV08. Whether you need undercarriage parts, hydraulic systems, or engine components, a supplier with a broad inventory ensures you’ll find what you need without delays.

“Having the right part at the right time can save you from costly downtime.”

3. Expert Guidance and Support

Sometimes, identifying the correct part for your excavator can feel overwhelming. A reliable supplier provides expert support to guide you through the process. YNF Machinery’s team helps you verify model numbers, match part codes, and ensure compatibility. Their expertise simplifies the selection process, so you can focus on keeping your equipment running smoothly.

4. Competitive Pricing and Value

A good supplier balances quality with affordability. YNF Machinery offers competitive pricing without compromising on durability or performance. This means you get long-lasting parts that provide excellent value for your investment. By choosing a supplier that prioritizes cost-effectiveness, you can manage your maintenance budget more efficiently.

5. Fast and Reliable Delivery

Timely delivery is crucial when your excavator needs repairs. Delays can halt your projects and increase costs. YNF Machinery understands this urgency and ensures quick shipping to get your parts to you as soon as possible. Their streamlined logistics make the entire process hassle-free.

Why YNF Machinery Stands Out

With their extensive experience, wide product range, and commitment to customer satisfaction, YNF Machinery sets itself apart as a trusted partner for Yanmar mini excavator owners. Their dedication to quality and support ensures you’ll always have the parts and assistance you need to keep your equipment performing at its best.

When you choose a reliable supplier like YNF Machinery, you’re not just buying parts—you’re investing in the longevity and efficiency of your excavator.

Overview of Essential Yanmar Mini Excavator Parts

When maintaining your Yanmar mini excavator, understanding the essential parts is key to keeping it in top condition.

Undercarriage Components for the Best Mini Excavator

The undercarriage forms the foundation of your mini excavator. It supports the machine’s weight and ensures stability during operation. High-quality parts like tracks, rollers, and sprockets are essential for maintaining balance and durability. Worn-out undercarriage components can lead to uneven wear and reduced efficiency.

Regular inspection of these parts helps you identify issues early. For example, checking the tension of the tracks prevents unnecessary strain on the system. Suppliers like YNF Machinery offer a wide range of undercarriage components designed to fit various Yanmar models. Their durable parts ensure your excavator performs reliably, even in challenging conditions.

“A well-maintained undercarriage extends the lifespan of your mini excavator and enhances its performance.”

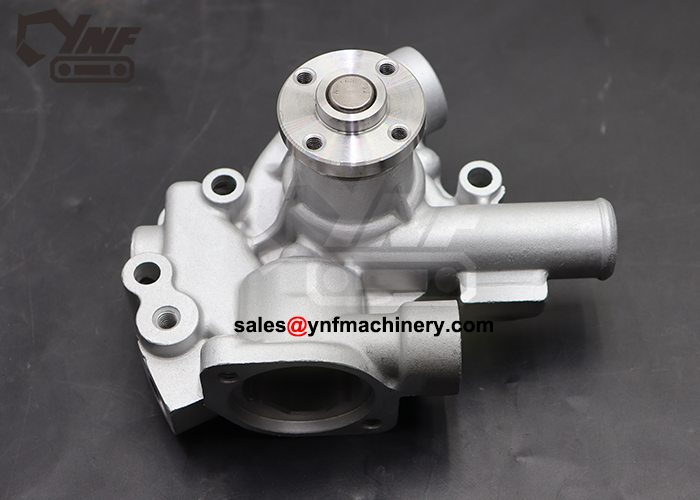

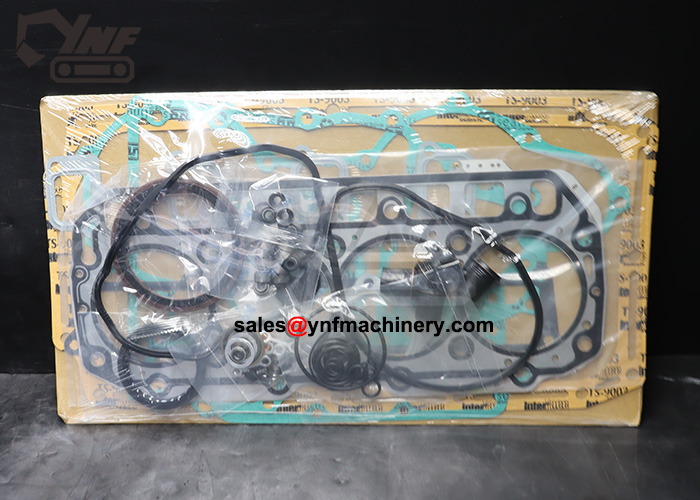

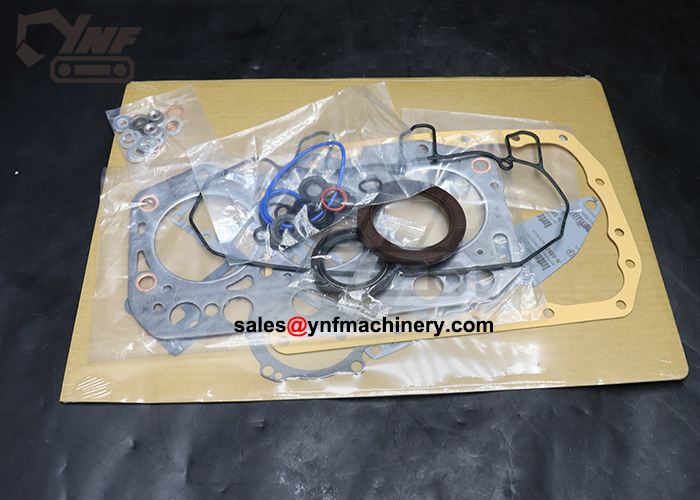

Hydraulic System Parts and Excavator Couplings

The hydraulic system powers most of your mini excavator’s functions, from digging to lifting.

Excavator couplings are another critical element. They connect the engine to the hydraulic pump, enabling power transmission. YNF Machinery provides durable couplings that withstand tough working conditions. Their products, such as Centaflex-A and Bowex couplings, offer flexibility and vibration isolation, ensuring seamless operation.

To maintain your hydraulic system, check for leaks and replace worn-out seals promptly. YNF Seals, for instance, offers specialized hydraulic cylinder seal kits that fit various excavator models. These kits help you address common issues and keep your system running efficiently.

Attachments and Accessories for Versatile Applications

Mini excavator attachments expand the versatility of your machine. Buckets, augers, and grapples allow you to tackle different tasks with ease. Choosing the right attachments depends on your project requirements and excavator size guide. For example, smaller buckets work well for precise digging, while larger ones handle bulk material efficiently.

Accessories like quick couplers make switching between attachments faster and more convenient. Investing in high-quality parts ensures these tools perform reliably. YNF Machinery offers a variety of attachments and accessories compatible with Yanmar mini excavators. Their products help you maximize productivity and adapt to diverse applications.

“The right attachments transform your mini excavator into a multi-functional powerhouse.”

By focusing on these essential parts, you can enhance the performance and longevity of your Yanmar mini excavator. Regular maintenance and timely replacements ensure your machine stays ready for any challenge.

Tips for Ensuring Compatibility and Performance

Verifying Model Numbers and Part Codes

Getting the right parts for your Yanmar mini excavator starts with verifying the model numbers and part codes. Every Yanmar excavator model has unique specifications, and using the wrong part can lead to operational issues or even damage. You’ll want to double-check these details before making a purchase.

Start by locating the model number of your excavator. This is usually found on a metal plate attached to the machine. Once you have the model number, look for the corresponding part codes in your user manual. These codes help you identify the exact components your excavator needs.

If you’re unsure about the codes, don’t hesitate to reach out to a trusted supplier like YNF Machinery. Their team can guide you through the process and ensure you select the correct parts. They also offer a wide range of components, making it easier to find what you need for models like B10, VIO10, or SV08.

“Matching the right part to your excavator model ensures smooth operation and prevents costly mistakes.”

By taking the time to verify these details, you’ll avoid unnecessary downtime and keep your equipment running efficiently.

Consulting Manuals and Experts (e.g., YNF Machinery Support)

Your excavator’s manual is one of the most valuable tools for ensuring compatibility and performance. It contains detailed information about the parts, maintenance schedules, and troubleshooting tips specific to your model. Always refer to it when you’re unsure about a part or repair process.

Sometimes, though, manuals might not provide all the answers you need. That’s when consulting experts becomes essential. Suppliers like YNF Machinery offer expert support to help you make informed decisions. Their team can assist with identifying parts, verifying compatibility, and even providing installation tips.

Here’s how you can make the most of expert guidance:

Ask Specific Questions: Provide details about your excavator model and the issue you’re facing. This helps the expert give precise recommendations.

Share Photos or Videos: Visuals can clarify the problem and make it easier for the expert to identify the right solution.

Follow Up: After receiving advice, confirm that the suggested part or solution works as expected.

YNF Machinery’s support team goes beyond just selling parts. They help you understand how to maintain your excavator for long-term performance. Their commitment to customer satisfaction ensures you’ll always have the assistance you need.

“Expert advice saves time and ensures you’re making the best choice for your equipment.”

By combining the knowledge from your manual with expert insights, you’ll confidently select parts that enhance your excavator’s performance.

Benefits of Using Genuine vs. Aftermarket Yanmar Mini Excavator Parts

When it comes to maintaining your Yanmar mini excavator, the choice between genuine and aftermarket parts can feel overwhelming. Both options have their merits, but understanding their differences helps you make the best decision for your equipment. Let’s break it down.

Advantages of Genuine Yanmar Mini Excavator Parts

Genuine parts are designed specifically for your Yanmar mini excavator. They come straight from the manufacturer, ensuring a perfect fit and optimal performance. Here’s why they’re worth considering:

Unmatched Compatibility: Genuine parts are tailored to meet the exact specifications of your excavator model. This eliminates the guesswork and ensures seamless operation. You won’t have to worry about whether the part will fit or function properly.

Superior Quality: These parts undergo rigorous testing to meet high standards. They’re built to last, even in tough working conditions. For example, genuine hydraulic components maintain efficiency under pressure, reducing the risk of leaks or failures.

Enhanced Operator Comfort: Genuine parts contribute to smoother machine performance, which directly impacts operator comfort. A well-maintained excavator runs more efficiently, reducing vibrations and noise during operation.

Manufacturer Support: When you choose genuine parts, you gain access to expert advice and support from Yanmar dealers. They can guide you on maintenance schedules, provide manuals, and help you select the right components for your machine.

“Using genuine parts ensures your excavator performs as the manufacturer intended, giving you peace of mind and long-term reliability.”

While genuine parts may come with a higher price tag, their durability and performance often make them a cost-effective choice in the long run.

Evaluating Aftermarket Options for Mini Excavator Parts

Aftermarket parts offer an alternative to genuine components. They’re produced by third-party manufacturers and can be a viable option for some excavator owners. Here’s what you need to know:

Cost Savings: Aftermarket parts are typically more affordable than genuine ones. If you’re working within a tight budget, they can help you save money upfront.

Wide Availability: Many suppliers offer a broad range of aftermarket parts, making it easier to find what you need. Companies like YNF Machinery provide high-quality aftermarket options that meet or exceed OEM standards.

Varied Quality: Not all aftermarket parts are created equal. Some match the quality of genuine components, while others fall short. To avoid issues, choose parts from reputable suppliers with a proven track record.

Potential Risks: Poorly made aftermarket parts can lead to compatibility issues, reduced performance, or even damage to your excavator. Always verify the specifications and consult experts before making a purchase.

“Aftermarket parts can be a smart choice if you prioritize cost savings, but quality should never be compromised.”

When evaluating aftermarket options, focus on finding parts that balance affordability with reliability. Trusted suppliers like YNF Machinery offer durable components that enhance operator comfort and keep your excavator running smoothly.

By weighing the benefits of genuine and aftermarket parts, you can make an informed decision that suits your needs. Whether you prioritize long-term reliability or immediate cost savings, the right choice ensures your Yanmar mini excavator stays in top condition.

Maintenance and Replacement Best Practices

Regular Inspection and Maintenance of Mini Excavator Parts

By checking your machine frequently, you can catch potential issues before they turn into costly repairs. A proactive approach ensures your excavator performs efficiently and lasts longer.

Start by examining critical components like the undercarriage, hydraulic system, and engine parts. Look for signs of wear, such as cracks, leaks, or unusual noises. For example, worn-out tracks or sprockets can affect stability and lead to uneven wear. Addressing these problems early prevents further damage.

Create a maintenance schedule to stay consistent. Include tasks like cleaning filters, lubricating moving parts, and tightening loose bolts. These small steps make a big difference in keeping your excavator running smoothly. Suppliers like YNF Machinery offer durable parts that withstand tough conditions, making maintenance easier and more effective.

“Regular maintenance is the key to extending the lifespan of your mini excavator and avoiding unexpected downtime.”

Don’t forget to use high-quality tools and products during maintenance. Genuine parts, like those from YNF Machinery, ensure compatibility and reliability. They’re designed to meet the exact specifications of your Yanmar model, giving you peace of mind.

Knowing When to Replace Parts for the Best Mini Excavator Performance

Recognizing when to replace parts is just as important as regular maintenance. Worn-out or damaged components can reduce your excavator’s efficiency and even cause safety hazards. Knowing the signs helps you act quickly and keep your machine in peak condition.

Here are some common indicators that it’s time to replace parts:

Decreased Performance: If your excavator struggles to lift, dig, or move as it should, the hydraulic system or engine parts might need attention.

Visible Wear and Tear: Cracks, rust, or frayed edges on components like hoses, belts, or couplings signal the need for replacement.

Unusual Noises: Grinding, squeaking, or knocking sounds often point to issues with moving parts, such as bearings or gears.

Leaks or Spills: Hydraulic fluid or oil leaks can indicate worn seals or damaged hoses.

When replacing parts, always choose high-quality options. Genuine Yanmar parts offer unmatched compatibility and durability.

“Investing in genuine parts safeguards your equipment’s reliability and reduces the risk of unexpected failures.”

Suppliers like YNF Machinery provide both genuine and high-grade aftermarket parts. Their expert support helps you identify the right components for your Yanmar mini excavator. With their guidance, you can make informed decisions and avoid costly mistakes.

By combining regular inspections with timely replacements, you’ll maximize your excavator’s performance and lifespan. A well-maintained machine not only saves you money but also ensures smooth operation for every project.

Choosing the right Yanmar mini excavator parts plays a vital role in keeping your equipment running smoothly and lasting longer. Genuine parts ensure top-notch performance, while trusted suppliers like YNF Machinery simplify the process with reliable options and expert support. Regular maintenance, such as inspecting undercarriage components or hydraulic systems, boosts efficiency and reduces downtime. By making informed decisions, you protect your investment and enhance your excavator’s capabilities. Explore YNF Machinery today to find high-quality parts tailored to your needs and keep your projects on track without hassle.

FAQ

What makes Yanmar mini excavator parts different from other brands?

Yanmar mini excavator parts are specifically designed to match the unique specifications of their equipment. Unlike parts for other mini excavator brands, Yanmar components ensure precise compatibility and optimal performance. Their parts undergo rigorous testing to meet high-quality standards, which helps extend the lifespan of your machine. By choosing Yanmar parts, you reduce the risk of operational issues and costly repairs.

“Yanmar parts are tailored for seamless integration, ensuring your excavator operates at its best.”

How do I know if a part is compatible with my Yanmar mini excavator?

To ensure compatibility, start by checking your excavator’s model number and part codes. These details are usually found on a metal plate attached to the machine or in the user manual. Trusted suppliers like YNF Machinery can assist you in verifying these details.

Are aftermarket parts a good option for Yanmar mini excavators?

Aftermarket parts can be a cost-effective alternative, but their quality varies. High-grade aftermarket parts from reputable suppliers, such as YNF Machinery, often meet or exceed OEM standards. However, poorly made aftermarket parts may compromise performance or cause damage. Always prioritize quality and consult experts before purchasing aftermarket components.

“Reliable aftermarket parts balance affordability with durability, making them a smart choice when sourced from trusted suppliers.”

Why should I choose genuine Yanmar parts over aftermarket options?

Genuine Yanmar parts guarantee unmatched compatibility and performance. They are manufactured to exact specifications, ensuring a perfect fit for your mini excavator. These parts also come with manufacturer support, which includes maintenance advice and warranty protection. While they may cost more upfront, their durability and reliability often make them a better long-term investment.

How often should I inspect and maintain my Yanmar mini excavator?

Regular inspections and maintenance are essential for keeping your excavator in top condition. Check critical components like the undercarriage, hydraulic system, and engine parts at least once a month. Look for signs of wear, such as leaks, cracks, or unusual noises. Following a consistent maintenance schedule helps you catch issues early and ensures optimal performance.

“Frequent maintenance not only extends your excavator’s lifespan but also enhances its efficiency.”

What are the benefits of using flexible rubber couplings in my excavator?

Flexible rubber couplings improve machinery performance by reducing vibrations and noise. They also compensate for misalignment, which minimizes wear and tear on connected components. By using high-quality couplings, like those offered by YNF Machinery, you enhance the efficiency and longevity of your excavator.

Can I use parts from other mini excavator brands in my Yanmar machine?

Using parts from other mini excavator brands is not recommended. Each brand designs its components to fit specific models, and mismatched parts can lead to operational issues or even damage. Stick to parts designed for Yanmar mini excavators to ensure compatibility and maintain performance.

How do I extend the lifespan of my Yanmar mini excavator?

To extend your excavator’s lifespan, focus on regular maintenance, timely replacement of worn-out parts, and using high-quality components. Genuine Yanmar parts or reliable aftermarket options from trusted suppliers like YNF Machinery help keep your machine running smoothly. Additionally, follow the maintenance guidelines in your user manual and consult experts when needed.

What should I do if I’m unsure about the part I need?

If you’re unsure about the part you need, consult your excavator’s manual or reach out to a trusted supplier like YNF Machinery. Their team can help you identify the correct part based on your model number and specific requirements. Providing photos or videos of the issue can also help experts guide you more effectively.

Why is regular maintenance important for Yanmar mini excavators?

Regular maintenance ensures your excavator performs efficiently and reduces the risk of unexpected breakdowns. It improves fuel economy, decreases emissions, and minimizes repair needs. By addressing issues early, you save money and keep your projects on track without delays.

“Maintenance is the cornerstone of reliable and efficient excavator operation.”