Excavators are indispensable in construction and mining. These machines rely on several essential parts of an excavator to perform tasks like digging, lifting, and moving materials. Each part plays a vital role in ensuring smooth operation. However, maintenance challenges like hydraulic system failures, undercarriage issues, and engine malfunctions can disrupt performance. Understanding the main parts of an excavator helps you address these problems effectively. YNF Machinery offers high-quality excavator components, including engine parts and couplings, to keep your equipment running efficiently. Their durable products ensure reliability even in tough conditions.

Key Takeaways

The undercarriage helps keep the excavator stable and moving. Checking tracks and wheels often improves how it works on different grounds.

The cab is where the operator controls the machine. Comfortable designs and easy-to-use controls help during long work hours.

The hydraulic system makes the excavator work. Taking care of the pump and cylinders keeps it running well and avoids delays.

Using the right tools makes the excavator more useful. Quick couplers make switching tools faster, safer, and easier.

Good engine parts improve how the machine works and lasts. Regular care and strong parts prevent breakdowns and lower costs.

The Undercarriage: Foundation of an Excavator

The undercarriage forms the backbone of an excavator, providing stability and mobility. It supports the machine’s weight and ensures smooth operation across various terrains. Understanding its components helps you maintain your excavator’s performance and durability.

Tracks and Wheels

Tracks: Provide stability and mobility on uneven terrain.

Tracks are essential for excavators operating in challenging environments. They distribute the machine’s weight evenly, reducing ground pressure and enhancing stability on soft or uneven surfaces. Tracks excel in muddy or sandy terrains, offering unmatched traction and minimizing the risk of sinking.

Materials like rubber are commonly used to construct tracks due to their durability and flexibility. Rubber absorbs shocks and vibrations, reducing operator fatigue. It also resists tears and cuts, maintaining its mechanical properties under repetitive cycles. These features make tracks reliable for heavy-duty tasks.

Wheels: Used in wheeled excavators for faster movement on flat surfaces.

Wheels are ideal for excavators working on well-paved or stable surfaces. They allow for higher speeds and easier transport between locations. While they lack the traction of tracks, wheels are practical for urban construction sites or areas requiring frequent movement. Choosing between tracks and wheels depends on your work environment and mobility needs.

Drive System

Motors and gears that power the movement of the tracks or wheels.

The drive system powers the undercarriage, enabling movement. Key components include:

Hydraulic Motor: Converts hydraulic fluid into mechanical power, driving the tracks or wheels.

Planetary Gear System: Reduces speed from the motor, ensuring efficient power transmission.

Sprocket: Engages with the tracks to transmit rotational motion, enhancing traction.

Housing and Seals: Protect internal components and prevent hydraulic fluid leaks.

This system ensures precise control, stability, and the ability to handle heavy loads. It also allows directional control by regulating hydraulic fluid flow.

Counterweight

Balances the machine to prevent tipping during operation.

The counterweight is a critical safety feature of the undercarriage. It offsets the weight of the boom, arm, and bucket during operation. This balance prevents the excavator from tipping, especially when lifting heavy loads or working on uneven ground. Proper counterweight placement ensures stability and enhances operational safety.

By understanding the undercarriage and its components, you can optimize your excavator’s performance and longevity. Regular maintenance of tracks, wheels, and the drive system ensures smooth operation, even in demanding conditions.

The Cab: Operator’s Control Center

The cab serves as the control center of an excavator, where you manage all operations. It combines comfort, functionality, and safety to ensure efficient performance during long working hours.

Operator’s Seat

Provides a comfortable and ergonomic space for the operator.

The operator’s seat is designed to maximize comfort and reduce fatigue. Modern excavators feature advanced ergonomic designs, including:

Heated/cooled air-suspension seats for temperature control.

Air-suspension systems that absorb shocks and vibrations.

Ergonomic joystick controls for effortless operation.

These features ensure you remain comfortable and focused, even during extended use. A well-designed seat minimizes strain, allowing you to operate the excavator efficiently.

Controls and Displays

Levers, pedals, and screens for controlling the excavator’s functions.

The controls and displays in the cab provide you with precise command over the excavator. Modern advancements have enhanced these systems to improve efficiency:

AI algorithms increase precision in tasks like digging and grading.

Electrohydraulic controls integrate sensors with hydraulic components for smoother operation.

2D grade control systems use GPS to ensure accurate slopes and elevations.

Telematics systems allow remote monitoring, helping you track maintenance and reduce downtime.

These innovations simplify complex tasks, enabling you to achieve better results with less effort.

Safety Features

Includes seat belts, reinforced glass, and climate control for operator safety.

Safety remains a top priority in excavator cabs. Features like seat belts and reinforced glass protect you from potential hazards. Seat belts, required by safety standards such as Section 1926.602(a), keep you secure during operation. Reinforced glass shields you from debris while maintaining visibility.

Additional safety measures include climate control systems, which regulate temperature and improve air quality. Rollover protective structures (ROPS) safeguard you in case of accidents. These features ensure a safe and comfortable working environment, allowing you to focus on operating the excavator effectively.

Hydraulic System: The Power Behind the Excavator

The hydraulic system powers the excavator, enabling it to perform heavy-duty tasks with precision and efficiency. This system uses pressurized hydraulic fluid to generate the force needed for movement and operation. Understanding its components helps you maintain your excavator’s performance and reliability.

Hydraulic Pump

Generates the pressure needed to power the excavator’s movements.

The hydraulic pump is the heart of the hydraulic system. It converts mechanical energy into hydraulic energy, ensuring the excavator operates smoothly. This pump plays a vital role in:

Controlling the flow and pressure of hydraulic fluid, which directly impacts performance.

Powering the movements of attachments like the boom, arm, and bucket.

Allowing precise control during digging, lifting, and other operations.

A well-maintained hydraulic pump ensures your excavator remains productive and efficient, even in demanding conditions.

Hydraulic Cylinders

Convert hydraulic pressure into mechanical force for lifting and digging.

Hydraulic cylinders are essential for transforming hydraulic energy into mechanical force. These components handle the heavy lifting and digging tasks of the excavator. Manufacturers use durable materials to ensure cylinders withstand high pressure and harsh environments.

Material | Properties | Applications | Pros | Cons |

|---|---|---|---|---|

Steel | High tensile strength, good machinability, excellent fatigue resistance | Heavy-duty applications like construction equipment | Affordable, readily available, withstands high pressures | Susceptible to corrosion if not treated |

Stainless Steel | Excellent corrosion resistance, high strength | Marine environments, chemical processing | Resistant to rust and corrosion | More expensive, challenging to machine |

Aluminum | Lightweight, good corrosion resistance | Aerospace, automotive, mobile hydraulics | Reduces overall weight | Lower strength than steel, can be expensive |

Composite Materials | High strength-to-weight ratio, excellent corrosion resistance | High-performance applications like aerospace | Extremely lightweight, high strength | High cost, complex manufacturing and repair |

Steel and stainless steel are common choices for excavator cylinders due to their strength and durability. Regular inspection and maintenance of these cylinders prevent leaks and ensure smooth operation.

Hydraulic Lines

Transport hydraulic fluid to various components.

Hydraulic lines connect the pump, cylinders, and other components, ensuring efficient fluid transport. These lines maintain the system’s pressure and reliability. The design of hydraulic systems allows for significant force generation in compact spaces, enabling the excavator to handle demanding tasks. Components like control valves and filtration systems work together to optimize performance. Proper care of hydraulic lines prevents leaks and ensures your excavator operates efficiently.

By understanding the hydraulic system and its components, you can keep your excavator in top condition. Regular maintenance of the pump, cylinders, and lines ensures consistent performance and reduces downtime.

Boom, Arm, and Bucket: The Core Working Components

The boom, arm, and bucket form the core working components of an excavator. These parts handle the machine’s primary digging functions, making them essential for productivity and efficiency.

Boom

The long arm attached to the cab that provides reach and height.

The boom is the excavator’s backbone for reaching high or distant areas. It connects directly to the cab and provides the height and reach needed for various tasks. For example, the long-reach version of the Volvo EC380 excavator has a boom length of 27′ 11″ (8.5 m), while its standard boom measures 21′ 2″ (6.45 m). This variation in boom dimensions allows you to choose the right model based on your project needs.

Different excavator models offer varying maximum reach capabilities. Here’s a quick comparison:

Model | Max Reach |

|---|---|

Volvo EC380E | 34′ 7″ |

Volvo EC480E | 39′ 10″ |

Volvo EC530E | 40′ 0″ |

Volvo EC550E | 40′ 0″ |

Volvo EC750E | 37′ 7″ |

Volvo EC950F | 46′ 0″ |

This table highlights how the boom’s reach can vary significantly, helping you select the right excavator for your specific tasks.

Arm

Connects the boom to the bucket and provides additional reach.

The arm acts as the link between the boom and the bucket. It extends the excavator’s reach, allowing you to dig deeper or farther. The arm’s design ensures smooth movement and precise control during operations. Its length and strength determine how effectively you can handle heavy loads or access hard-to-reach areas. Regular maintenance of the arm ensures consistent performance and prevents wear over time.

Bucket

The digging tool used for scooping, lifting, and moving materials.

The bucket is the excavator’s primary tool for digging and material handling. Its size and capacity depend on several factors:

Type of Material: Denser materials, like rocks, require smaller buckets to maintain efficiency and reduce fuel consumption.

Job Site Conditions: Narrow spaces or unstable ground may necessitate smaller buckets for safety and precision.

Obstructions: Areas with obstacles demand smaller buckets to avoid damage and ensure accuracy.

You can also choose larger buckets for loose materials like sand or gravel to maximize productivity. Selecting the right bucket ensures optimal performance and reduces wear on the excavator.

By understanding the boom, arm, and bucket, you can maximize your excavator’s efficiency and adapt it to various tasks. Regular inspection and maintenance of these components will keep your machine in top condition.

Attachments and Couplings: Enhancing Excavator Versatility

Excavators become even more versatile when equipped with the right attachments and couplings. These components allow you to adapt your machine to a wide range of tasks, enhancing productivity and efficiency.

Common Attachments

Augers, breakers, and grapples for specialized tasks.

Attachments transform your excavator into a multi-functional tool. Each attachment serves a specific purpose, helping you tackle various challenges on the job site. Some of the most commonly used attachments include:

Digging Buckets: Perfect for creating foundations, excavating trenches, and removing stumps. Their teeth make them ideal for breaking through hard soil.

Rock Buckets: Designed for rocky terrain and heavy demolition, these buckets feature hardened teeth for durability.

Grading Buckets: Equipped with a flat edge, these buckets excel at smoothing surfaces and landscaping.

Augers: Use these hydraulic spiral blades for quick drilling and digging, especially in construction or landscaping projects.

Hydraulic Hammers: Break through hard surfaces like concrete or frozen ground with ease.

Grapple Buckets: Handle difficult materials like debris or scrap metal, making them indispensable for demolition sites.

By selecting the right attachment, you can maximize your excavator’s potential and complete tasks more efficiently.

Quick Coupler

Allows for easy switching between attachments.

Quick couplers simplify the process of changing attachments, saving you valuable time. Traditional methods of switching attachments can take up to 20 minutes, but quick couplers reduce this significantly. For example, if you perform 10 attachment changes daily, you could save up to 200 minutes of work time.

Traditional Change Time | Quick Coupler Change Time | Time Saved |

|---|---|---|

Up to 20 minutes | Significantly less | Up to 20 minutes |

Quick couplers also allow you to switch attachments without leaving the cab. This feature enhances safety and convenience, especially when frequent changes are required. By reducing downtime, quick couplers ensure you always use the right tool for the job, preventing unnecessary wear on your excavator.

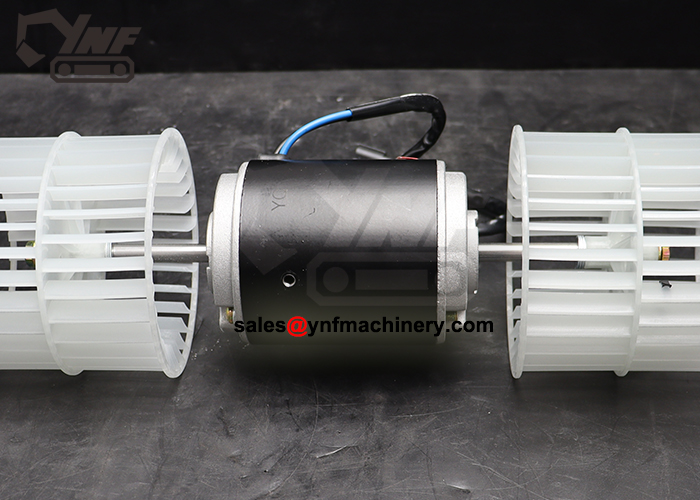

YNF Machinery’s Excavator Couplings

Ensure efficient power transmission between the engine and hydraulic pump system.

Couplings play a crucial role in maintaining your excavator’s performance. YNF Machinery offers high-quality excavator couplings that ensure smooth power transmission between the engine and hydraulic pump system. These couplings are built to withstand tough working conditions, minimizing downtime and maximizing productivity.

YNF Machinery provides a variety of coupling types, including Centaflex-A and Bowex models, which offer flexibility and vibration isolation. Their durable construction ensures long-lasting performance, making them a reliable choice for your excavator. By investing in YNF Machinery’s couplings, you can enhance your machine’s efficiency and reduce maintenance needs.

The Engine: Heart of the Excavator

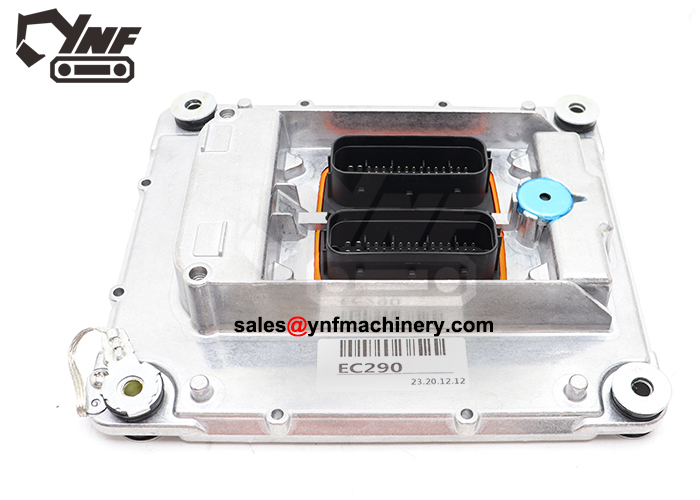

Excavator Engine Parts by YNF Machinery

High-quality components like pistons, cylinders, and crankshafts for optimal performance.

The engine is the powerhouse of your excavator, and its components play a vital role in ensuring smooth operation. YNF Machinery provides high-quality engine parts, including pistons, cylinders, and crankshafts, designed to withstand the demands of heavy-duty tasks. These parts are crafted from durable materials, ensuring they can handle high temperatures, pressure, and friction. By using reliable components, you reduce the risk of breakdowns and extend the lifespan of your machine.

High-quality engine parts also offer environmental benefits. Advanced engineering improves fuel efficiency and reduces emissions. This not only saves you money but also helps your company meet environmental regulations and sustainability goals. Investing in premium parts ensures your excavator operates efficiently while minimizing its environmental impact.

Engine Functionality

Powers the excavator, providing energy for all operations.

The engine generates the power needed to drive your excavator’s hydraulic system and other components. This power enables the movement of the boom, arm, and bucket, directly influencing the machine’s performance. Without a well-functioning engine, your excavator cannot perform essential tasks like digging, lifting, or moving materials.

The engine also powers the final drive, which transmits energy to the tracks. This process converts hydraulic energy into mechanical energy, ensuring smooth movement and operational efficiency. Regular maintenance is crucial to prevent engine failures. Check oil levels, inspect air filters, and use high-quality fuel to keep your engine running smoothly. Proper operator training also prevents overloading and reduces stress on the engine.

By understanding the importance of the engine and its components, you can maintain your excavator’s performance and reliability. A well-maintained engine ensures your machine remains productive, even in challenging conditions.

The main parts of an excavator work together to deliver exceptional performance. Understanding these components helps you operate the machine efficiently and maintain it effectively. For example, knowing the cab’s controls improves safety, while regular maintenance of the hydraulic system minimizes downtime. High-quality parts, like those from YNF Machinery, reduce long-term costs by preventing frequent replacements. By learning how the boom, arm, and bucket function, you can troubleshoot issues and extend the excavator’s lifespan. This knowledge ensures your machine operates safely and remains productive for years.

FAQ

What are the most important parts of an excavator to maintain regularly?

You should focus on the hydraulic system, engine, and undercarriage. Check hydraulic fluid levels, inspect engine components like filters and belts, and clean tracks or wheels. Regular maintenance prevents breakdowns and ensures smooth operation.

How do I choose the right attachment for my excavator?

Select attachments based on your task. For digging, use buckets. For breaking concrete, choose hydraulic hammers. Consider material type, job site conditions, and required precision. Quick couplers make switching attachments easier.

Why is the counterweight important for excavators?

The counterweight balances the machine during operation. It prevents tipping when lifting heavy loads or working on uneven ground. Proper counterweight placement ensures safety and stability, especially during demanding tasks.

How can I extend the lifespan of my excavator?

Perform regular maintenance, use high-quality parts, and avoid overloading. Inspect hydraulic lines, clean filters, and lubricate moving parts. Follow the manufacturer’s guidelines for operation and servicing. Proper care reduces wear and increases longevity.

What makes YNF Machinery’s parts reliable?

YNF Machinery uses durable materials and advanced engineering. Their parts meet or exceed OEM standards, ensuring compatibility and performance. With rigorous quality checks, YNF Machinery provides reliable components that withstand tough conditions, reducing downtime and maintenance costs.