Yanmar excavators deliver exceptional reliability, but even the best machines face wear and tear over time. Certain components, like hydraulic systems and engine parts, endure heavy use and often require attention. Recognizing these vulnerable areas allows you to plan maintenance effectively. For instance, a diesel mechanic once shared how servicing injectors and overhauling cylinder heads significantly extended engine life. By sourcing Yanmar excavator parts online, you can ensure timely repairs and keep your equipment running smoothly, avoiding costly downtime.

Key Takeaways of choosing Yanmar Excavator Parts Online

Regularly inspect hydraulic hoses for cracks and leaks to prevent costly repairs and ensure optimal performance.

Maintain proper tension and alignment of tracks to extend their lifespan and reduce wear on undercarriage components.

Replace filters (air, oil, fuel) at regular intervals to protect your engine from contaminants and maintain efficiency.

Conduct routine diagnostics to identify electrical issues early, preventing unexpected downtime and ensuring smooth operation.

Choose high-quality replacement parts from trusted suppliers like YNF Machinery to enhance reliability and reduce maintenance costs.

Implement a structured maintenance schedule to stay on top of essential tasks and minimize the risk of breakdowns.

Train operators on best practices to improve machine handling and reduce wear on components, extending the life of your excavator.

Common Hydraulic System Components for Repairs

ydraulic systems play a vital role in the performance of your Yanmar excavator. These components endure constant pressure and heavy workloads, making them prone to wear. Understanding common issues with hydraulic parts helps you maintain your equipment effectively and avoid unexpected breakdowns.

Hydraulic Hoses and Their Maintenance

Causes of Wear and Tear in Hydraulic Hoses

Hydraulic hoses in your Yanmar excavator face extreme conditions daily. High-pressure fluid flow, exposure to heat, and abrasive materials contribute to their deterioration. Over time, these factors weaken the hose material, causing cracks or leaks. Improper installation or using incompatible fluids can also accelerate wear. Regular inspection of hoses ensures you catch early signs of damage.

Signs of Damage and Replacement Tips

Damaged hydraulic hoses often show visible cracks, bulges, or leaks. You may also notice reduced hydraulic performance or unusual noises during operation. When replacing hoses, choose high-quality options compatible with your Yanmar excavator. Ensure proper installation by securing fittings tightly and avoiding sharp bends. Routine maintenance extends the lifespan of your hoses and prevents costly repairs.

Hydraulic Cylinders and Seals

Why Seals and Rods Fail Frequently

Hydraulic cylinders in Yanmar excavators rely on seals to maintain pressure and prevent leaks. These seals often fail due to contamination, excessive pressure, or improper lubrication. Scratches or dents on the cylinder rod can also damage seals, leading to fluid leakage. Regular cleaning and using the correct hydraulic fluid reduce the risk of failure.

Preventing Leaks with Proper Maintenance

To prevent leaks, inspect the cylinder rods and seals for wear or damage. Replace worn seals promptly to avoid further complications. Keep the hydraulic fluid clean by using high-quality filters and replacing them as needed. Proper maintenance ensures your Yanmar excavator operates efficiently and minimizes downtime.

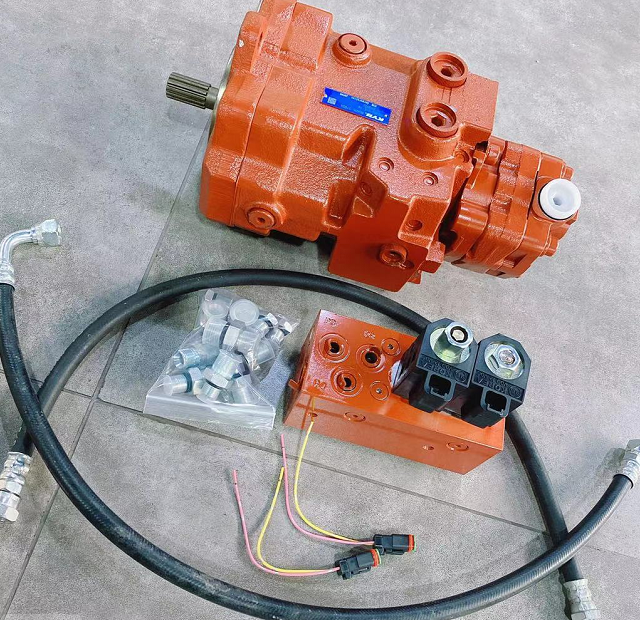

Hydraulic Pumps and Performance Issues

Common Causes of Hydraulic Pump Failure

Hydraulic pumps in Yanmar excavators often fail due to contamination, overheating, or insufficient lubrication. Dirt or debris entering the system damages internal components, reducing pump efficiency. Operating the excavator with low hydraulic fluid levels or using the wrong type of fluid can also lead to pump failure. Regularly checking fluid levels and maintaining a clean system prevents these issues.

How to Address Performance Problems

If your hydraulic pump shows signs of reduced performance, such as slow operation or unusual noises, address the issue immediately. Start by inspecting the fluid for contamination and replacing it if necessary. Check for leaks or damaged components within the pump system. If problems persist, consult a professional to repair or replace the pump. Using genuine Yanmar parts ensures optimal performance and reliability.

Undercarriage Parts That Require Frequent Repairs

The undercarriage of your Yanmar excavator endures constant stress during operation. It supports the machine’s weight and ensures smooth movement across various terrains. Regular inspection and maintenance of undercarriage parts help you avoid costly repairs and extend the lifespan of your equipment.

Tracks (Rubber and Steel)

Why Tracks Wear Out Quickly

Tracks, whether rubber or steel, face significant wear due to continuous contact with rough surfaces. Rubber tracks often experience chunking and tearing when exposed to sharp debris or uneven terrain. Steel tracks, while more durable, can suffer from bending or cracking under heavy loads. Improper tension and misalignment also accelerate track deterioration. Frequent use in harsh environments, such as rocky or muddy areas, further contributes to their wear.

Tips for Extending Track Life

To maximize the life of your tracks, follow these essential tips:

Maintain Proper Tension: Check track tension regularly. Over-tightened tracks increase stress on the undercarriage, while loose tracks risk slipping off.

Inspect Tracks Daily: Look for signs of damage, such as cracks, tears, or missing chunks. Address minor issues promptly to prevent further damage.

Choose the Right Tracks for the Job: Use rubber tracks for smoother surfaces and steel tracks for rugged terrains. Rubber tracks provide better handling and reduce ground damage, while steel tracks offer superior durability.

Clean Tracks After Use: Remove dirt, rocks, and debris lodged in the tracks. This prevents unnecessary wear and ensures smooth operation.

By implementing these practices, you can reduce downtime and keep your Yanmar excavator running efficiently.

Rollers, Idlers, and Sprockets

Common Issues with Rollers and Idlers

Rollers and idlers play a crucial role in supporting and guiding the tracks. Over time, these parts may develop flat spots, cracks, or excessive wear due to constant friction and pressure. Lack of lubrication often accelerates their deterioration. Misaligned tracks can also cause uneven wear on rollers and idlers, leading to reduced performance.

To prevent these issues, inspect rollers and idlers regularly. Ensure proper alignment and apply high-quality lubricants to minimize friction. Replacing worn-out components promptly avoids further damage to the undercarriage.

When to Replace Sprockets for Optimal Performance

Sprockets engage with the tracks to drive the excavator forward. Worn sprockets can cause track slippage, uneven movement, and increased stress on other undercarriage parts. Look for signs of wear, such as rounded or chipped teeth. If you notice excessive noise or reduced traction, it may be time to replace the sprockets.

Replacing sprockets at the right time ensures optimal performance and prevents damage to the tracks. Always choose high-quality sprockets compatible with your Yanmar excavator for reliable operation.

Engine Components and Their Maintenance

Proper maintenance of engine components is essential for keeping your Yanmar excavator running efficiently. By focusing on critical parts like filters, belts, hoses, and cooling systems, you can prevent costly breakdowns and extend the life of your machine. Understanding the importance of high-quality components ensures optimal performance and reliability.

Filters (Air, Oil, and Fuel)

Importance of Regular Filter Replacement

Filters play a vital role in protecting your Yanmar engine from contaminants. Air filters ensure clean airflow, oil filters remove impurities from the lubrication system, and fuel filters prevent debris from entering the engine. Over time, these filters accumulate dirt and lose their effectiveness. Replacing them at regular intervals maintains engine efficiency and prevents damage to internal components.

Using a Maintenance Filter Kit simplifies this process. These kits include all necessary filters, ensuring you have the right components for your excavator. High-quality filters not only trap particles effectively but also enhance overall engine performance. Regular replacement minimizes wear and tear, reducing the risk of unexpected failures.

Signs of Clogged or Failing Filters

Clogged filters often show clear signs. Reduced engine power, increased fuel consumption, or unusual noises may indicate a problem. A dirty air filter restricts airflow, causing the engine to work harder. A clogged oil filter can lead to poor lubrication, increasing friction and heat. Similarly, a failing fuel filter disrupts fuel delivery, resulting in rough operation or stalling.

Inspect filters regularly and replace them if you notice these symptoms. Clean filters keep your Yanmar engine running smoothly, ensuring consistent performance and longevity.

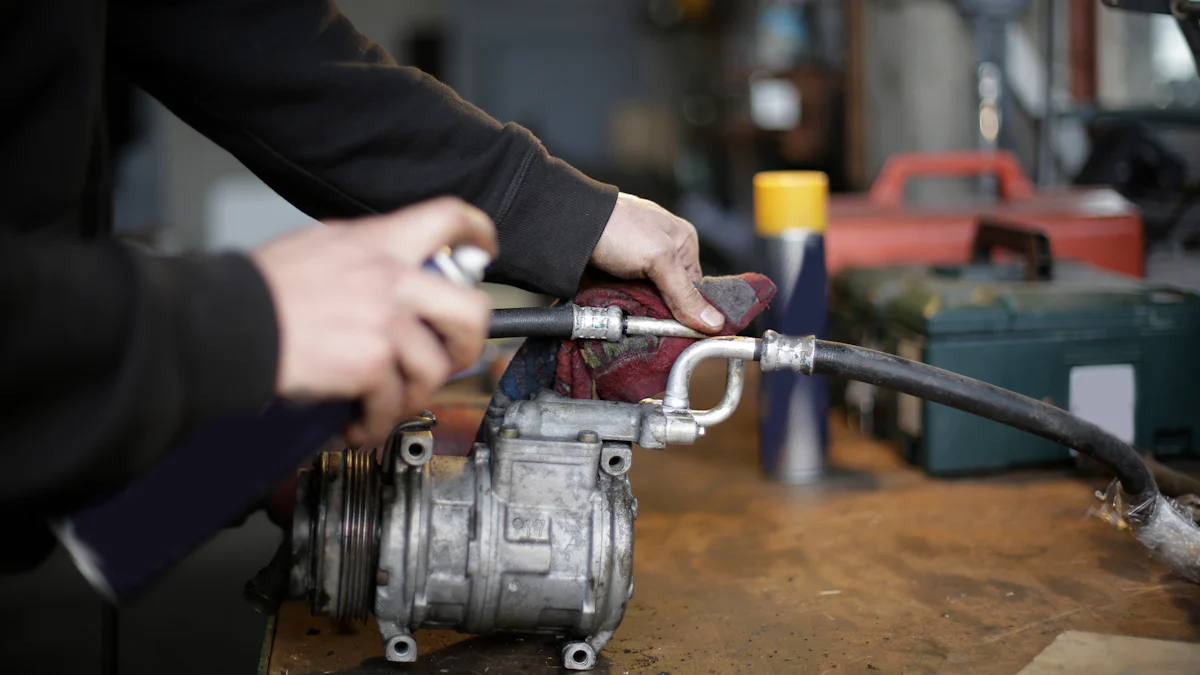

Belts, Hoses, and Cooling Systems

Why Belts and Hoses Are Prone to Cracking

Belts and hoses in your Yanmar excavator endure constant stress. High temperatures, pressure fluctuations, and exposure to harsh conditions cause these components to degrade over time. Rubber belts may crack or fray, while hoses can develop leaks due to wear or improper installation. Ignoring these issues can lead to engine overheating or failure.

Regular inspection helps you identify early signs of damage. Replace worn belts and hoses promptly to avoid further complications. Choosing durable, high-quality replacements ensures reliability and reduces maintenance costs.

Preventing Overheating in Cooling Systems

The cooling system in your Yanmar excavator prevents the engine from overheating. Components like radiators, water pumps, and coolant hoses must function properly to maintain optimal temperature. Blockages, leaks, or low coolant levels can compromise the system, leading to severe engine damage.

To prevent overheating, check coolant levels frequently and inspect hoses for leaks. Clean the radiator to remove debris that may obstruct airflow. Using a reliable water pump, such as the Kyotechs 352-0211 Water Pump, ensures efficient cooling and extends the life of your Yanmar engine.

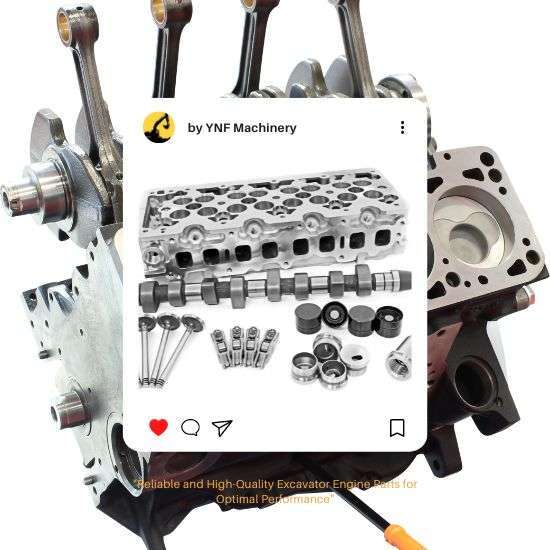

Excavator Engine Parts from YNF Machinery

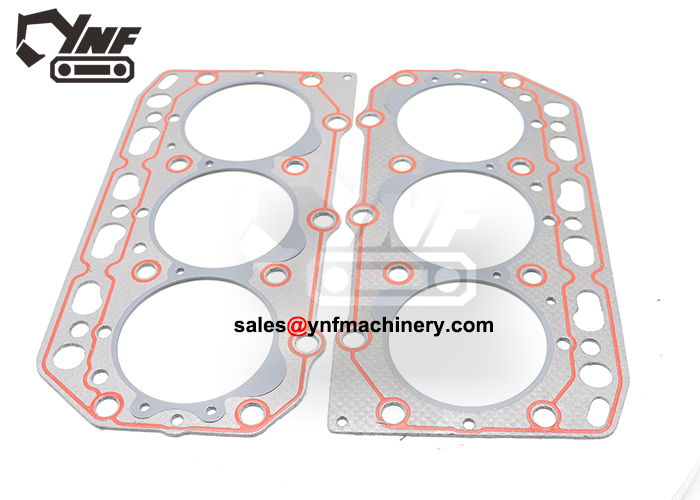

High-Quality Engine Components for Longevity

YNF Machinery offers a wide range of engine parts designed to meet the demands of Yanmar excavators. These components, including pistons, crankshafts, and gaskets, are engineered for durability and efficiency. By using high-quality materials, YNF Machinery ensures that their parts withstand harsh conditions and deliver consistent performance.

Investing in reliable engine components reduces downtime and maintenance costs. YNF Machinery’s products undergo rigorous quality checks, providing you with peace of mind and confidence in your equipment.

Benefits of Using YNF Machinery’s Engine Parts while choosing Yanmar Excavator Parts Online

Choosing YNF Machinery for your Yanmar engine parts offers several advantages. Their components are compatible with various excavator models, ensuring a perfect fit and easy installation. The availability of both OEM and aftermarket options provides flexibility, allowing you to select parts that suit your needs and budget.

By sourcing parts from YNF Machinery, you benefit from competitive pricing without compromising on quality. Their commitment to customer satisfaction ensures a seamless purchasing experience, with expert support and fast shipping. High-quality engine parts from YNF Machinery enhance the performance and longevity of your Yanmar excavator, keeping your operations running smoothly.

Electrical System Parts and Troubleshooting

Electrical components in your Yanmar excavator play a critical role in ensuring smooth operation. Issues with these parts can lead to unexpected downtime. Understanding common problems and their solutions helps you maintain your equipment effectively.

Batteries and Wiring

Causes of Battery Failure and Maintenance Tips

Batteries in your Yanmar excavator often fail due to improper charging, extreme temperatures, or prolonged inactivity. Corrosion on terminals and loose connections also contribute to performance issues. Over time, batteries lose their ability to hold a charge, especially if they are not maintained properly.

To extend battery life:

Inspect Terminals Regularly: Clean corrosion using a mixture of baking soda and water. Tighten loose connections to ensure proper power flow.

Monitor Voltage Levels: Use a multimeter to check the battery’s voltage. Replace it if the readings fall below the recommended range.

Store Batteries Correctly: Keep them in a cool, dry place when not in use. Avoid exposing them to extreme heat or cold.

Charge Properly: Use a charger compatible with your Yanmar excavator’s battery. Avoid overcharging, as it can damage internal components.

Routine maintenance ensures reliable performance and reduces the risk of sudden failures.

Troubleshooting Common Wiring Issues

Wiring problems often cause electrical malfunctions in your Yanmar excavator. Damaged wires, loose connections, or faulty fuses disrupt the flow of electricity. Identifying and addressing these issues promptly prevents further complications.

Follow these steps to troubleshoot wiring problems:

Inspect Visible Wires: Look for signs of wear, such as fraying, cuts, or burns. Replace damaged wires immediately.

Check Connections: Ensure all connectors are secure. Loose connections can cause intermittent power loss.

Test Fuses: Use a fuse tester to identify blown fuses. Replace them with ones that match the specified amperage.

Use a Multimeter: Measure voltage at different points in the circuit to locate breaks or faults.

Proper wiring maintenance keeps your Yanmar excavator’s electrical system functioning efficiently.

Sensors and Control Modules

Why Sensors Fail and How to Replace Them

Sensors in your Yanmar excavator monitor various systems, such as engine performance and hydraulic pressure. These sensors fail due to contamination, exposure to extreme conditions, or electrical surges. A malfunctioning sensor often triggers warning lights or causes erratic machine behavior.

To replace a faulty sensor:

Identify the Problematic Sensor: Use diagnostic tools to pinpoint the issue. Refer to your Yanmar excavator’s manual for sensor locations.

Disconnect Power: Turn off the machine and disconnect the battery to avoid electrical shocks.

Remove the Old Sensor: Unscrew or unclip the sensor carefully. Avoid damaging surrounding components.

Install the New Sensor: Secure it in place and reconnect any wires or plugs. Test the system to ensure proper functionality.

Replacing sensors promptly ensures accurate readings and optimal machine performance.

Importance of Regular Diagnostics

Regular diagnostics help you identify potential issues before they escalate. Modern Yanmar excavators come equipped with advanced control modules that store error codes. These codes provide valuable insights into the health of your machine.

Benefits of regular diagnostics include:

Early Detection: Identify worn components or system inefficiencies before they cause major failures.

Improved Performance: Addressing minor issues enhances overall machine efficiency.

Cost Savings: Preventative maintenance reduces repair costs and minimizes downtime.

Invest in a reliable diagnostic tool compatible with your Yanmar excavator. Perform routine checks to keep your equipment in top condition.

Attachments and Wear Parts for Yanmar Excavators

Attachments and wear parts play a crucial role in the efficiency and versatility of your Yanmar excavator. These components endure heavy use and often require regular maintenance or replacement. By understanding their functionality and addressing wear promptly, you can maximize your excavator’s performance and lifespan.

Buckets, Teeth, and Quick Couplers

Why Bucket Teeth Wear Out Quickly

Bucket teeth are among the most frequently replaced parts on a Yanmar excavator. These teeth endure constant contact with abrasive materials like rocks, gravel, and soil. Over time, this exposure causes significant wear, reducing their digging efficiency. Improper usage, such as applying excessive force or using the wrong bucket for the task, accelerates wear. For example, using a standard bucket for trenching in rocky terrain can quickly damage the teeth.

To minimize wear, inspect the teeth regularly for signs of chipping or dullness. Replace worn teeth promptly to maintain optimal digging performance. High-quality bucket teeth, like those included in Yanmar Mini Excavator Parts, offer durability and reliability, ensuring they withstand tough conditions.

Ensuring Proper Attachment Functionality

Attachments like buckets and quick couplers must function seamlessly to ensure smooth operations. Misaligned or poorly maintained attachments can lead to inefficiencies and even damage other components. Regularly check the attachment points for wear or looseness. Tighten bolts and replace worn pins to secure the connection.

Quick couplers simplify the process of switching between attachments, saving time and effort. However, they require proper care to maintain their functionality. Clean the coupler mechanism after each use to remove debris that may hinder its operation. Investing in durable attachments, such as Strickland Yanmar Excavator Digger Buckets & Attachments, ensures long-lasting performance and reduces downtime.

Pins, Bushings, and Excavator Couplings

Reducing Friction in Pins and Bushings

Pins and bushings are essential for the smooth movement of your Yanmar excavator’s attachments. These components experience constant friction during operation, leading to wear over time. Lack of lubrication is a common cause of premature wear, resulting in increased resistance and reduced efficiency.

To reduce friction, apply high-quality lubricants to the pins and bushings regularly. Inspect these parts for signs of wear, such as elongation or scoring, and replace them as needed. Using robust options like those found in Yanmar Mini Excavator Parts ensures durability and reliable performance. Proper maintenance of pins and bushings not only extends their lifespan but also enhances the overall efficiency of your excavator.

YNF Machinery’s Durable Excavator Couplings

Excavator couplings are vital for transmitting power between the engine and hydraulic systems. High-quality couplings ensure smooth operation and reduce the risk of machinery failure. YNF Machinery’s Durable Excavator Couplings stand out for their robust construction and ability to withstand harsh conditions. These couplings compensate for misalignment and absorb vibrations, protecting your excavator from unnecessary stress.

By choosing YNF Machinery’s couplings, you benefit from components designed for longevity and efficiency. Their compatibility with various Yanmar excavator models makes them a reliable choice for operators seeking dependable solutions. Regular inspection and timely replacement of worn couplings prevent unexpected breakdowns and keep your equipment running smoothly.

Maintenance Tips to Prevent Frequent Repairs

Proper maintenance is the cornerstone of keeping your Yanmar excavator in top condition. By adopting effective practices, you can reduce the frequency of repairs and extend the lifespan of your equipment. Below are actionable tips to help you maintain your excavator efficiently.

Regular Inspection and Servicing

Key Areas to Inspect During Maintenance

Routine inspections are essential for identifying potential issues before they escalate into costly repairs. Focus on these critical areas during maintenance:

Hydraulic System: Check for leaks, worn hoses, and low fluid levels. Inspect the hydraulic pump and cylinders for signs of wear or damage.

Undercarriage: Examine tracks, rollers, idlers, and sprockets for wear. Look for cracks, misalignment, or missing components.

Engine Components: Inspect filters, belts, and hoses. Ensure the cooling system operates efficiently by checking coolant levels and radiator cleanliness.

Electrical System: Test the battery, wiring, and sensors. Look for corrosion, loose connections, or damaged wires.

By addressing these areas regularly, you can prevent unexpected breakdowns and keep your Yanmar excavator running smoothly.

How to Create a Maintenance Schedule

A well-structured maintenance schedule ensures you stay on top of essential tasks. Follow these steps to create an effective plan:

Refer to the Operator’s Manual: Use the Yanmar manual to identify recommended service intervals for your excavator model.

Set Regular Checkpoints: Schedule daily, weekly, and monthly inspections. For example, check fluid levels daily and perform a full undercarriage inspection monthly.

Track Maintenance Activities: Keep a log of completed tasks, including filter replacements, oil changes, and part inspections.

Use Reminders: Set alerts for upcoming maintenance tasks to ensure nothing gets overlooked.

A consistent schedule minimizes downtime and helps you avoid costly repairs.

Proper Operation Techniques

How Operator Habits Impact Part Longevity

The way you operate your Yanmar excavator directly affects the longevity of its parts. Poor habits can lead to premature wear and frequent repairs. Common mistakes include:

Overloading: Exceeding the machine’s capacity strains the hydraulic system and undercarriage.

Abrupt Movements: Jerky controls increase stress on pins, bushings, and couplings.

Ignoring Warning Signs: Operating with unusual noises or reduced performance can worsen existing issues.

Adopting smooth and controlled movements reduces stress on components. Avoid overworking the machine to ensure parts last longer.

Training Tips for Operators

Proper training equips operators with the skills needed to handle the excavator efficiently. Consider these tips:

Understand the Controls: Familiarize yourself with the Yanmar excavator’s controls and features. Practice smooth operation to minimize wear.

Follow Best Practices: Use the right attachments for each task. For example, choose rubber tracks for soft surfaces and steel tracks for rugged terrains.

Stay Alert: Monitor the machine’s performance during operation. Address unusual sounds or vibrations immediately.

Investing in operator training not only improves efficiency but also reduces the likelihood of repairs.

Sourcing Yanmar Excavator Parts Online

Benefits of Buying Genuine Parts Online

Purchasing genuine Yanmar excavator parts online offers several advantages. Authentic parts ensure compatibility and reliability, reducing the risk of further damage. Here’s why buying online is beneficial:

Convenience: Access a wide range of parts from the comfort of your home or office.

Availability: Find hard-to-source components quickly, including engine parts, hydraulic pumps, and filters.

Cost-Effectiveness: Compare prices across suppliers to get the best deals without compromising quality.

Using genuine parts enhances your excavator’s performance and minimizes the need for frequent repairs.

Trusted Suppliers Like YNF Machinery

When sourcing Yanmar excavator parts online, choosing a reliable supplier is crucial. YNF Machinery stands out as a trusted provider with over 35 years of experience. Here’s what makes them a preferred choice:

High-Quality Products: YNF Machinery offers durable parts that meet or exceed OEM standards.

Wide Selection: Find everything from engine components to hydraulic couplings, all compatible with Yanmar excavators.

Expert Support: Get assistance in selecting the right parts for your machine. YNF Machinery’s team ensures a seamless purchasing experience.

By partnering with reputable suppliers like YNF Machinery, you can maintain your excavator’s efficiency and reduce downtime.

Recommendations for Replacement Parts and Upgrades

Choosing High-Quality Replacement Parts

Factors to Consider When Selecting Parts

Selecting the right replacement parts for your Yanmar excavator ensures optimal performance and reduces the risk of frequent repairs. To make the best choice, focus on these key factors:

Compatibility: Ensure the part matches your excavator model. Using incompatible parts can lead to inefficiencies or even damage.

Quality Standards: Look for parts manufactured under strict quality systems, such as ISO9001. For example, Yanmar Genuine Parts meet industry-leading standards, ensuring durability and reliability.

Material Durability: Choose parts made from high-quality materials that can withstand harsh working conditions. Durable materials reduce wear and extend the lifespan of your equipment.

Supplier Reputation: Purchase from trusted suppliers with a proven track record. Reliable suppliers provide authentic parts and excellent customer support.

By considering these factors, you can avoid unnecessary downtime and maintain the efficiency of your Yanmar excavator.

Why YNF Machinery Is a Trusted Supplier

When it comes to sourcing replacement parts, YNF Machinery stands out as a reliable partner. With over 35 years of experience, YNF Machinery offers high-quality components designed to meet or exceed OEM standards. Their extensive product range includes everything from hydraulic pumps to engine parts, ensuring compatibility with various Yanmar excavator models.

YNF Machinery prioritizes customer satisfaction by providing competitive pricing and expert support. Their parts undergo rigorous quality checks, guaranteeing reliable performance. Whether you need durable couplings or efficient engine components, YNF Machinery delivers solutions that enhance your excavator’s longevity and efficiency.

Upgrading to More Durable Components

When to Consider Upgrades for Better Performance

Upgrading certain components of your Yanmar excavator can significantly improve its performance and reduce maintenance needs. Consider upgrades in the following scenarios:

Frequent Repairs: If a specific part requires constant replacement, upgrading to a more durable option can save time and money.

Harsh Working Conditions: Excavators operating in extreme environments benefit from components designed for higher durability.

Performance Issues: Upgrades can address inefficiencies, such as slow hydraulic response or engine overheating.

For instance, replacing a standard water pump with the Kyotechs 352-0211 Water Pump ensures better cooling efficiency and longer service life. Upgrading at the right time prevents costly breakdowns and enhances overall productivity.

Examples of Durable Aftermarket Options

Durable aftermarket options provide an excellent alternative to standard parts, offering enhanced performance and reliability. Here are some examples:

Ignition Systems: The Kyotechs 283-3074 Ignition Switch ensures seamless ignition operations, improving machine reliability.

Hydraulic Components: High-quality hydraulic pumps and hoses reduce the risk of leaks and maintain consistent performance under pressure.

Engine Parts: Upgraded pistons, crankshafts, and gaskets from trusted suppliers like YNF Machinery deliver exceptional durability and efficiency.

Investing in durable aftermarket components minimizes downtime and extends the lifespan of your Yanmar excavator. These upgrades not only improve performance but also reduce long-term maintenance costs.

Regular maintenance ensures your Yanmar excavator operates at peak performance. By identifying parts prone to wear, you can take proactive steps to prevent costly breakdowns. Establishing a maintenance routine minimizes downtime and extends the life of your equipment. High-quality parts, like those from trusted suppliers such as YNF Machinery, enhance reliability and efficiency. Investing in durable components not only reduces repair frequency but also protects your excavator’s long-term value. Keep your machine running smoothly by prioritizing proper care and using dependable replacement parts.

FAQ

How can you ensure the longevity of your Yanmar excavator’s hydraulic pump?

To keep your hydraulic pump in excellent condition, focus on regular maintenance. Check fluid levels frequently and use only the recommended hydraulic fluid for your machine. Clean the system to prevent contamination, as dirt and debris can damage internal components. If you notice reduced performance or unusual noises, address the issue immediately. Following these steps ensures optimal performance and extends the life of your hydraulic pump.

Pro Tip: Regular inspections and timely replacements of worn parts can save you from costly repairs down the line.

What are the signs that your Yanmar excavator’s tracks need replacement?

Worn tracks often show visible cracks, tears, or missing chunks. You may also notice reduced traction or uneven movement during operation. Steel tracks might bend or crack under heavy loads, while rubber tracks can chunk or tear on rough terrain. Inspect your tracks daily and replace them promptly to maintain smooth operation and prevent further damage.

Why is it important to replace filters regularly in your Yanmar excavator?

Filters protect your engine by preventing contaminants from entering critical systems. Over time, air, oil, and fuel filters accumulate dirt, reducing their effectiveness. Clogged filters can lead to poor engine performance, increased fuel consumption, or even system failures. Replacing filters at regular intervals ensures clean airflow, proper lubrication, and efficient fuel delivery.

How do you troubleshoot wiring issues in your Yanmar excavator?

Start by inspecting visible wires for fraying, cuts, or burns. Check all connections to ensure they are secure. Use a fuse tester to identify blown fuses and replace them with the correct amperage. A multimeter can help you locate breaks or faults in the circuit. Addressing wiring issues promptly prevents electrical malfunctions and keeps your excavator running smoothly.

What causes bucket teeth to wear out quickly, and how can you extend their life?

Bucket teeth wear out due to constant contact with abrasive materials like rocks and gravel. Improper usage, such as using the wrong bucket for the task, accelerates wear. To extend their life, inspect the teeth regularly and replace them when they become dull or chipped. Use high-quality bucket teeth designed for durability and reliability.

How can you reduce friction in pins and bushings?

Apply high-quality lubricants to pins and bushings regularly. Inspect these components for signs of wear, such as elongation or scoring, and replace them as needed. Proper lubrication minimizes friction, enhances efficiency, and extends the lifespan of your excavator’s attachments.

What are the benefits of using YNF Machinery’s excavator parts?

YNF Machinery offers high-quality parts that meet or exceed OEM standards. Their components are durable, reliable, and compatible with various Yanmar excavator models. By choosing YNF Machinery, you benefit from competitive pricing, expert support, and fast shipping. These advantages ensure your excavator operates efficiently and reduces downtime.

When should you consider upgrading components in your Yanmar excavator?

Upgrades are beneficial when parts require frequent replacement, your machine operates in harsh conditions, or you experience performance issues. For example, upgrading to a more durable water pump improves cooling efficiency and extends service life. Timely upgrades enhance productivity and reduce long-term maintenance costs.

How do you create an effective maintenance schedule for your Yanmar excavator?

Refer to your operator’s manual for recommended service intervals. Schedule daily, weekly, and monthly inspections. Track completed tasks, such as filter replacements and part inspections, in a maintenance log. Use reminders to stay on top of upcoming tasks. A consistent schedule minimizes downtime and ensures your excavator remains in top condition.

Why should you buy genuine Yanmar parts online?

Genuine parts ensure compatibility and reliability, reducing the risk of further damage. Buying online offers convenience, a wide selection, and cost-effectiveness. Trusted suppliers like YNF Machinery provide authentic parts, expert support, and fast shipping, making it easier to maintain your excavator’s efficiency.