The demand for aftermarket parts continues to rise as businesses seek cost-effective solutions for maintaining equipment like the John Deere 70D excavator parts. In 2026, the global aftermarket parts market is projected to grow significantly, reaching USD 1560.31 million by 2032 with a CAGR of 8.40%. This growth reflects the increasing reliance on aftermarket components to extend the lifespan of older machinery. While OEM parts offer unmatched quality and reliability, aftermarket parts provide a more affordable alternative. Trusted suppliers like YNF Machinery ensure you can access high-quality options, including excavator couplings and engine parts, tailored to your needs.

Key Takeaways

-

Aftermarket parts are a cheaper way to fix your John Deere 70D excavator. They save money and still work well.

-

Picking trusted sellers like YNF Machinery gives you good-quality parts. These parts can be as good as or better than original ones.

-

It’s important to check part numbers and details. This makes sure the parts fit your excavator perfectly.

-

Using aftermarket parts can make your machine last longer. You won’t need repairs or new parts as often.

-

Choosing aftermarket parts helps the environment by cutting waste and saving materials in construction.

What Are Aftermarket Parts?

Definition of Aftermarket Parts

Aftermarket parts refer to components and services available after the initial sale of construction equipment. These parts are designed to improve the performance and extend the lifespan of machinery like excavators, trucks, and cranes. They serve as replacements or upgrades, helping you reduce downtime and keep your equipment running efficiently. For older models such as the John Deere 70D excavator, aftermarket parts provide a practical solution when original parts are no longer available.

Purpose and Role of Aftermarket Parts

The primary purpose of aftermarket parts is to offer cost-effective alternatives to original equipment manufacturer (OEM) parts. They play a crucial role in maintaining and repairing heavy machinery, ensuring that your equipment remains operational even under challenging conditions. Aftermarket parts also allow you to customize your machines to meet specific needs. As the construction industry evolves, these parts have become essential for businesses looking to balance performance with affordability.

In an era where customization is key, aftermarket parts allow you to modify your equipment to suit your unique requirements.

Additionally, technological advancements have made aftermarket parts more adaptable and reliable. This shift has increased their popularity among contractors and equipment owners who value flexibility and cost savings.

How Aftermarket Parts Differ from OEM Parts

Aftermarket parts differ from OEM parts in several ways:

-

They are produced by third-party manufacturers, often at a lower cost.

-

OEM parts are made by the original manufacturer, ensuring they meet the exact specifications of your equipment.

-

Aftermarket parts can offer innovative solutions by addressing flaws found in OEM parts.

-

Delivery times and customer service vary, with aftermarket parts sometimes requiring more effort to integrate into your supply chain.

-

While OEM parts are considered the highest quality, aftermarket parts provide a more affordable alternative without necessarily compromising reliability.

Many misconceptions surround aftermarket parts. For example, some believe that lower prices mean lower quality. However, aftermarket parts often meet the same standards as OEM parts. Others think OEM parts are easier to find, but for older models like the John Deere 70D excavator, aftermarket options are often more accessible.

Comparison of Aftermarket, New, and Used John Deere 70D Excavator Parts

Cost Comparison

Price Range for New Parts

New parts for the John Deere 70D excavator often come with a premium price tag. These parts are manufactured by the original equipment manufacturer (OEM) and meet exact specifications. You can expect to pay significantly more for new parts due to their unmatched quality and durability. While they ensure long-term reliability, the high cost may not always align with your budget, especially for older equipment.

Price Range for Used Parts

Used parts offer a more affordable alternative. Their prices vary depending on the condition, availability, and demand. Some used parts may function effectively, but others might require frequent maintenance. A thorough inspection is essential before purchasing to ensure you get value for your money. While used parts can save you money upfront, their long-term reliability may not match that of new or aftermarket options.

Price Range for Aftermarket Parts

Aftermarket parts strike a balance between cost and quality. They are typically more affordable than new parts and offer better reliability than many used options. Trusted suppliers like YNF Machinery provide high-quality aftermarket parts that meet or exceed OEM standards. This makes them a cost-effective choice for maintaining your John Deere 70D excavator without compromising performance.

Quality and Performance

Durability of New Parts

New parts deliver the highest durability and require minimal maintenance. They are designed to last, ensuring your excavator operates efficiently for years. However, their high cost may not always justify the investment for older models.

Reliability of Used Parts

Used parts can vary in reliability based on their condition and previous usage. Some may perform well, while others might need frequent repairs. A detailed inspection is crucial to assess their suitability for your equipment.

Performance of Aftermarket Parts

Aftermarket parts offer reliable performance at a fraction of the cost of new parts. Many aftermarket options, like those from YNF Machinery, are engineered to address flaws in OEM designs, enhancing their functionality. These parts provide a dependable solution for maintaining older equipment like the John Deere 70D excavator.

|

Part Type |

Durability |

Maintenance Needs |

Performance |

Cost-Effectiveness |

|---|---|---|---|---|

|

New Parts |

Highest |

Minimal |

Long-lasting |

High |

|

Used Parts |

Variable |

Frequent |

Condition-dependent |

Moderate |

|

Aftermarket Parts |

Reliable |

Moderate |

Near-original |

High |

Availability and Accessibility

Lead Times for New Parts

New parts often have longer lead times due to manufacturing and shipping processes. This can delay repairs and impact your project timelines.

Availability of Used Parts

Used parts are generally more accessible, especially for older models. However, their availability depends on market demand and the condition of salvaged equipment.

Market for Aftermarket Parts

The aftermarket parts market continues to grow, offering a wide range of options for various excavator models. Suppliers like YNF Machinery ensure you can find compatible parts quickly, reducing downtime and keeping your equipment operational.

Advantages of Aftermarket John Deere 70D Excavator Parts

Cost Savings and Affordability

Aftermarket parts offer a practical way to save money without sacrificing quality. These parts are generally more affordable than original equipment manufacturer (OEM) components. For owners of the John Deere 70D excavator, this affordability can make a significant difference, especially during large-scale projects where repair costs can quickly add up. By choosing aftermarket parts, you can maintain your equipment’s performance while keeping expenses under control. This cost-effective approach ensures that your excavator remains operational without straining your budget.

Tip: Investing in high-quality aftermarket parts from trusted suppliers like YNF Machinery can help you achieve long-term savings by reducing the need for frequent replacements.

Wide Range of Options

The aftermarket industry provides a vast selection of parts, giving you the flexibility to find exactly what you need. This variety benefits owners of older models like the John Deere 70D excavator in several ways:

-

You can access affordable alternatives to OEM components.

-

High-quality parts are readily available, ensuring timely repairs.

-

The wide range of options supports the longevity of older equipment.

This extensive availability means you can address specific maintenance needs without delays. Whether you require excavator couplings, engine parts, or other components, aftermarket suppliers like YNF Machinery ensure you have access to reliable solutions.

Compatibility with Older Models

Finding parts for older equipment can be challenging, but aftermarket options simplify the process. Many aftermarket parts are designed to fit older models like the John Deere 70D excavator, ensuring seamless compatibility. This compatibility allows you to keep your machine running efficiently, even when OEM parts are no longer in production. By choosing aftermarket components, you can extend the lifespan of your excavator and avoid the costly process of replacing the entire machine.

️ Note: Always verify compatibility before purchasing to ensure the part meets your equipment’s specifications.

YNF Machinery’s Role in Providing Reliable Aftermarket Parts

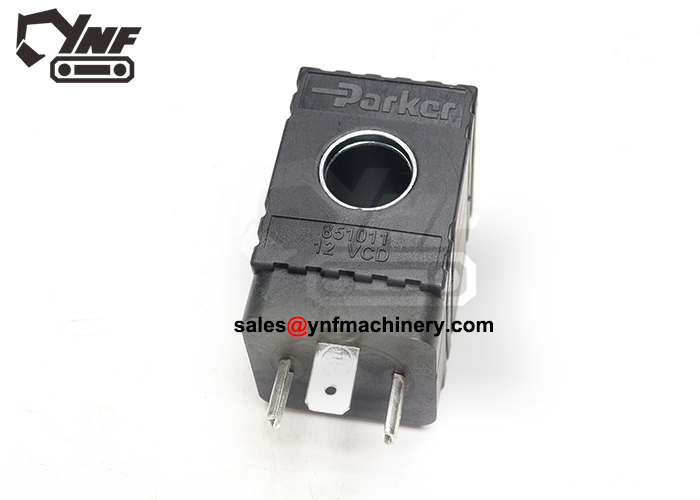

When it comes to maintaining your John Deere 70D excavator, YNF Machinery stands out as a trusted supplier of aftermarket parts. With over 35 years of experience, the company has built a reputation for delivering high-quality components that meet the demands of heavy-duty applications. Whether you need excavator couplings, engine parts, or other essential components, YNF Machinery ensures you have access to reliable solutions.

One of the key advantages of choosing YNF Machinery is the durability of its parts. Designed to withstand tough working conditions, these components ensure your equipment operates efficiently and reliably. The company also simplifies the process of sourcing parts. Its extensive dealer network and user-friendly online catalog make it easy for you to find and order the parts you need, reducing downtime and keeping your projects on track.

Here’s a quick overview of what YNF Machinery offers:

|

Feature |

Description |

|---|---|

|

Quality and Durability |

YNF Machinery parts are designed to withstand heavy-duty applications, ensuring operational reliability. |

|

Easy Access to Parts |

A vast dealer network and online catalog facilitate quick ordering and reduce downtime. |

By choosing YNF Machinery, you gain access to a wide range of aftermarket parts that are compatible with older models like the John Deere 70D excavator. This compatibility ensures you can maintain your equipment without the hassle of searching for hard-to-find components. The company’s commitment to quality and customer satisfaction makes it a reliable partner for your machinery needs.

️ Pro Tip: Regular maintenance with high-quality aftermarket parts can extend the lifespan of your excavator and improve its performance.

YNF Machinery not only provides parts but also supports you with expert advice and technical assistance. This comprehensive approach ensures you can keep your equipment running smoothly, even in challenging conditions.

Environmental and Sustainability Considerations

Environmental Impact of New Parts

Manufacturing new parts for excavators consumes significant energy and raw materials. This process impacts the environment by increasing carbon emissions and depleting natural resources. The supply chain for new parts also affects fuel efficiency due to transportation and production demands. The following table highlights the environmental impact of different types of parts:

|

Type of Part |

Environmental Impact |

|---|---|

|

New Parts |

Significant energy consumption and raw material usage, affecting fuel efficiency. |

|

Used Parts |

Reduces landfill waste and conserves resources, lowering the carbon footprint. |

|

Uses approximately 70% less raw material and consumes less energy, enhancing efficiency. |

By understanding these impacts, you can make informed decisions that align with your sustainability goals.

Benefits of Reusing Used Parts

Reusing used parts offers several environmental benefits. This practice reduces the demand for new parts, which minimizes the environmental impact of manufacturing. It also decreases the amount of metal that needs to be mined, processed, and transported. Here are some key advantages of reusing used parts:

-

Reduces landfill waste by reusing components.

-

Limits the need for producing new materials, conserving energy and natural resources.

-

Lowers the carbon footprint of the construction sector.

By choosing used parts, you contribute to a more sustainable construction industry while keeping your equipment operational.

Sustainability of Aftermarket Parts

Aftermarket parts play a vital role in promoting sustainability. These parts enhance energy efficiency, leading to lower fuel consumption and reduced greenhouse gas emissions. They also enable precise control of machinery, minimizing material waste and improving resource utilization. High-quality aftermarket parts extend the lifespan of your equipment, reducing the frequency of replacements and repairs. This approach decreases waste generation and supports a circular economy.

Tip: Opting for aftermarket parts not only saves money but also helps protect the environment by reducing waste and conserving resources.

By integrating aftermarket parts into your maintenance strategy, you can achieve both operational efficiency and environmental responsibility.

Recycling and Waste Reduction

Recycling plays a crucial role in reducing waste and conserving resources. When you choose aftermarket parts for your John Deere 70D excavator, you actively contribute to waste reduction efforts. These parts often come from recycled or rebuilt components, which helps minimize the amount of waste sent to landfills. By reusing materials, you support a more sustainable construction industry.

Aftermarket parts significantly lower the demand for new materials. For instance, rebuilt components use about 70% less raw material compared to manufacturing new ones. This process conserves valuable metals and minerals while reducing energy consumption. As a result, you help decrease the environmental impact of mining and production activities.

♻️ Did You Know? Recycled excavator parts not only reduce landfill waste but also lower the carbon footprint of construction projects.

Using aftermarket parts also promotes a circular economy. Instead of discarding old machinery, you can refurbish and reuse its components. This approach extends the lifecycle of materials, ensuring fewer resources are wasted. Additionally, aftermarket suppliers like YNF Machinery prioritize quality, ensuring these recycled parts perform reliably in demanding conditions.

|

Benefit |

Impact |

|---|---|

|

Reduced Landfill Waste |

Less discarded machinery and components. |

|

Conservation of Resources |

Lower demand for raw materials like metals and minerals. |

|

Energy Savings |

Rebuilt parts consume significantly less energy during production. |

By opting for aftermarket parts, you take a step toward sustainability. This choice not only saves money but also helps protect the environment. Every part you reuse or recycle contributes to a cleaner, greener future for the construction industry.

Tip: Partner with trusted suppliers like YNF Machinery to ensure high-quality recycled parts for your excavator.

Key Factors to Consider When Choosing Aftermarket John Deere 70D Excavator Parts

Compatibility with the John Deere 70D Excavator

Ensuring compatibility is the first step when selecting aftermarket parts for your John Deere 70D excavator. Each component must fit perfectly and function seamlessly with your machine. Precision-engineered parts simplify installation and reduce the risk of operational issues. For example, aftermarket parts manufactured in Japan are known for their high-quality engineering, offering durability and reliability. Always verify the part number and specifications to avoid mismatches. This practice ensures that your excavator operates efficiently without unnecessary downtime.

️ Tip: Look for parts that come with complete kits, such as sprockets and fitting tools, to streamline the replacement process.

Manufacturer Reputation and Reviews

The reputation of the manufacturer plays a critical role in your decision-making process. Trusted suppliers like YNF Machinery have built their credibility over decades by delivering reliable aftermarket parts. Customer reviews provide valuable insights into the quality of products and services. For instance:

-

Customers often praise knowledgeable staff and prompt communication.

-

Positive experiences, such as receiving great pricing and direct support from managers, highlight excellent customer service.

-

Reliable availability of in-stock or sourced parts ensures timely repairs.

John Deere excavators already enjoy a strong reputation for their performance and after-sales support. Choosing a reputable aftermarket supplier ensures that your machine continues to meet high standards, even with replacement parts.

Warranty and Return Policies

A solid warranty and clear return policies protect your investment. These policies demonstrate the manufacturer’s confidence in their products. When evaluating aftermarket parts, prioritize suppliers offering warranties that cover defects or performance issues. This assurance allows you to address potential problems without incurring additional costs. Return policies also matter, especially if you encounter compatibility issues or receive damaged parts.

Note: Always review the warranty terms and conditions before purchasing to avoid surprises later.

By considering these factors, you can confidently choose aftermarket parts that enhance the performance and longevity of your John Deere 70D excavator.

Cost vs. Long-Term Value

Aftermarket parts for the John Deere 70D excavator offer a cost-effective solution for maintaining your equipment. These parts are generally less expensive than OEM components, making them an attractive option for budget-conscious operators. However, affordability does not mean sacrificing quality. Many aftermarket parts meet or exceed OEM standards, ensuring reliable performance over time.

When you choose aftermarket parts, you save money upfront and reduce long-term expenses. High-quality aftermarket components often last as long as OEM parts, minimizing the need for frequent replacements. This durability translates into fewer repairs and less downtime, which can significantly impact your overall operational costs. For older models like the John Deere 70D excavator, aftermarket parts provide excellent value by extending the machine’s lifespan without breaking the bank.

Tip: Investing in durable aftermarket parts from trusted suppliers ensures you get the best balance between cost and long-term value.

Availability of Technical Support

Access to technical support is crucial when maintaining your excavator. Aftermarket parts suppliers often provide comprehensive assistance to help you make informed decisions. Here’s what you can expect:

-

A wide range of new aftermarket, used, and rebuilt parts for the John Deere 70D excavator.

-

Contact options, including phone calls or online quote requests, for quick support.

-

Resources like detailed catalogs to help you browse and select the right parts.

-

Technical manuals divided into repair and diagnostics sections.

-

Repair sections guide you through component repairs.

-

Diagnostic sections help you identify and resolve routine failures efficiently.

-

This level of support ensures you can maintain your equipment with confidence, even if you’re new to using aftermarket parts.

Why YNF Machinery is a Trusted Choice for Excavator Couplings and Engine Parts

YNF Machinery has earned its reputation as a reliable supplier of aftermarket parts for heavy machinery. Their products stand out for their quality and durability, designed to withstand the demands of heavy-duty applications. Whether you need excavator couplings or engine parts, YNF Machinery ensures you receive components that perform reliably under tough conditions.

Their vast dealer network and efficient online catalog make it easy to find and order parts, reducing downtime for your projects. YNF Machinery also prioritizes customer satisfaction. Their team goes above and beyond to provide exceptional service, building trust and confidence in their products. By choosing YNF Machinery, you gain access to high-quality parts and a partner dedicated to supporting your equipment needs.

️ Pro Tip: Partnering with YNF Machinery ensures you receive durable parts and expert support, keeping your excavator running smoothly.

Aftermarket parts in 2026 offer a cost-effective and reliable solution for maintaining your John Deere 70D excavator. These parts provide significant savings compared to new components, allowing you to allocate resources to other operational needs. Choosing reputable suppliers like YNF Machinery ensures you receive durable, high-quality parts that reduce long-term replacement costs. Reliable suppliers also maintain steady inventories, helping you avoid delays caused by supply chain disruptions.

By evaluating your equipment’s needs and sourcing from trusted providers, you can extend your excavator’s lifespan while supporting sustainability. Investing in aftermarket parts is a smart choice for balancing performance, affordability, and environmental responsibility.

FAQ

1. How do you ensure compatibility when buying aftermarket parts for the John Deere 70D excavator?

Check the part number and specifications of your equipment. Compare these details with the product description provided by the supplier. Trusted suppliers like YNF Machinery offer expert support to help you confirm compatibility before purchasing.

️ Tip: Always double-check measurements and model numbers to avoid mismatches.

2. Are aftermarket parts as durable as OEM parts?

High-quality aftermarket parts often match or exceed OEM standards. Suppliers like YNF Machinery design their components to withstand tough conditions, ensuring durability and reliable performance.

Note: Choose parts from reputable suppliers to guarantee long-lasting results.

3. What are the cost benefits of using aftermarket parts?

Aftermarket parts cost less than OEM components while maintaining similar quality. They reduce upfront expenses and minimize long-term repair costs. This affordability makes them an excellent choice for older models like the John Deere 70D excavator.

Pro Tip: Invest in durable aftermarket parts to save money over time.

4. How do you find a reliable supplier for aftermarket parts?

Look for suppliers with a strong reputation, positive customer reviews, and years of experience. YNF Machinery, with over 35 years in the industry, offers high-quality parts and excellent customer service.

Advice: Check for warranties and return policies to ensure a risk-free purchase.

5. Do aftermarket parts come with warranties?

Yes, many aftermarket parts include warranties. These warranties cover defects or performance issues, giving you peace of mind. YNF Machinery provides warranty options on their products, ensuring you receive reliable components.

✅ Reminder: Review warranty terms before buying to understand what’s covered.