Maintaining your Mitsubishi mini excavator starts with choosing the right parts. Durable components ensure your machine operates efficiently and safely. Incompatible parts often lead to issues like improper installations or electrical malfunctions, which can disrupt performance. Low-quality materials or contaminated fuel can also damage the engine. High-quality Mitsubishi mini excavator parts, like those from trusted suppliers, help you avoid these problems. They enhance reliability and extend the lifespan of your equipment, saving you time and money in the long run.

Key Takeaways

Pick good-quality Mitsubishi mini excavator parts for safe use. Strong parts lower the chance of problems and improve how it works.

Always check if the parts fit your excavator model. This avoids setup problems and keeps everything working well.

Buy parts made from tough materials. Strong materials last longer and need fewer replacements.

Look at both OEM and trusted aftermarket parts. OEM parts fit perfectly, and good aftermarket ones can save money while working well.

Choose sellers with warranties and helpful customer service. This makes sure you get good parts and help when needed.

Why Choosing the Right Mitsubishi Mini Excavator Parts Matters

Impact on Excavator Performance

The performance of your Mitsubishi mini excavator depends heavily on the quality of its parts. Low-quality components can lead to several issues that reduce efficiency. You may notice slower operational speed, reduced power, and less precise movements. These problems often stem from quick wear and tear on engine components or hydraulic systems. For example, clogged injectors can lower combustion efficiency, making your excavator less effective. Using high-quality Mitsubishi mini excavator parts ensures smooth operation and consistent performance, allowing you to complete tasks efficiently.

Ensuring Safety and Reliability

Safety should always be a top priority when operating heavy machinery. Faulty or substandard parts can compromise the reliability of your excavator, increasing the risk of accidents. Regular breakdowns caused by poor-quality components can disrupt your workflow and create unsafe conditions on-site. Reliable Mitsubishi mini excavator parts enhance the stability and dependability of your equipment. By investing in trusted parts, you reduce the likelihood of unexpected failures, ensuring a safer working environment for you and your team.

Extending the Lifespan of Your Equipment

Your excavator is a significant investment, and extending its lifespan is essential for maximizing its value. High-quality parts play a crucial role in reducing wear and tear on critical systems. For instance, durable hydraulic components minimize the risk of frequent breakdowns, while efficient engine parts lower fuel consumption and operating costs. Choosing the right Mitsubishi mini excavator parts helps maintain your machine’s condition, reducing the need for costly repairs or replacements. This approach not only saves money but also ensures your excavator remains operational for years to come.

Key Considerations When Selecting Mitsubishi Mini Excavator Parts

Compatibility with Your Excavator Model

Identifying the Correct Model and Specifications

Ensuring compatibility starts with identifying your excavator’s exact make and model. You should verify the dimensions, mounting points, and operational requirements of the part you need. This step prevents installation issues and ensures the part performs as expected. For example, a hydraulic pump coupling must match the shaft diameter and spline count of your excavator. Always consult your equipment manual or contact a trusted supplier for guidance.

Avoiding Issues with Mismatched Parts

Mismatched parts can lead to operational inefficiencies and costly repairs. Using incompatible components may cause improper fitment, leading to wear and tear on surrounding systems. To avoid these problems, prioritize sourcing parts specifically designed for your Mitsubishi mini excavator. High-quality, compatible parts ensure smooth operation and reduce the risk of breakdowns.

Material Quality and Durability

Importance of High-Grade Materials

The material quality of excavator parts directly impacts their durability and performance. High-grade materials withstand harsh conditions, reducing the frequency of replacements. For instance, bronze bushings offer excellent wear resistance and strength, making them ideal for moving parts. Investing in durable materials ensures your excavator operates efficiently, even in demanding environments.

How to Spot Signs of Poor-Quality Parts

Identifying poor-quality parts can save you from future headaches. Look for uneven finishes, substandard packaging, or a lack of proper documentation. Inferior materials often fail under stress, leading to frequent breakdowns. Trusted suppliers like YNF Machinery provide parts that meet or exceed OEM standards, ensuring reliability and longevity.

Material Type | Properties | Applications |

|---|---|---|

Bronze Bushings | High wear resistance, strength, and corrosion resistance | Excavator joints and moving parts |

Solid Aluminum Bronze | Robust nature, capable of withstanding heavy loads and harsh conditions | Heavy-duty applications |

Premium Bronze Bushings | Superior wear resistance, strength, and custom sizing available | Demanding applications and harsh environments |

Manufacturer vs. Aftermarket Parts

Benefits of OEM Parts

Original Equipment Manufacturer (OEM) parts guarantee compatibility and quality. These parts are designed specifically for your Mitsubishi mini excavator, ensuring optimal performance. OEM parts often come with warranties, providing peace of mind. While they may cost more upfront, their reliability reduces long-term expenses.

Evaluating Aftermarket Options for Cost-Effectiveness

Aftermarket parts offer a cost-effective alternative, often saving you 15 to 30 percent compared to OEM options. Some aftermarket suppliers provide customized parts tailored to specific site requirements. However, you should carefully evaluate the supplier’s reputation and product quality. Reliable aftermarket parts can perform as well as, or even better than, OEM components, making them a practical choice for budget-conscious operators.

Tip: Whether you choose OEM or aftermarket parts, always prioritize quality and compatibility to maximize your excavator’s efficiency and lifespan.

Warranty and Support

Why Warranties Are Crucial

Warranties provide you with peace of mind when purchasing replacement parts. They act as a safety net, ensuring you receive a product that meets quality standards. If a part fails prematurely, a warranty allows you to request a replacement or repair without additional costs. This protection saves you money and reduces downtime for your equipment.

When buying mitsubishi mini excavator parts, always check the warranty terms. Look for details like the coverage period and what issues the warranty includes. A longer warranty often indicates the manufacturer’s confidence in their product. Reliable suppliers, such as YNF Machinery, offer warranties that reflect their commitment to quality. This assurance helps you avoid unexpected expenses and ensures your excavator operates efficiently.

Assessing Customer Support from Suppliers

Customer support plays a vital role in your purchasing experience. A supplier with excellent support can guide you in selecting the right parts and assist with any issues after the purchase. Before choosing a supplier, evaluate their responsiveness and willingness to help. Reach out with questions about compatibility or installation to test their expertise.

Suppliers like YNF Machinery provide comprehensive support, including technical advice and documentation. This level of service ensures you get the correct parts for your excavator. Reliable customer support also helps you resolve problems quickly, minimizing delays in your operations. Always prioritize suppliers who value your satisfaction and provide ongoing assistance.

️ Pro Tip: Choose suppliers that offer both warranties and strong customer support. This combination ensures you receive high-quality parts and reliable service for long-term success.

Where to Buy Reliable Mitsubishi Mini Excavator Parts

Authorized Dealers

Benefits of Purchasing from Official Mitsubishi Dealers

Buying from official Mitsubishi dealers ensures you receive genuine parts designed specifically for your excavator. These parts meet strict quality standards, guaranteeing compatibility and performance. Authorized dealers often provide warranties, giving you peace of mind about your purchase. Additionally, they offer expert advice to help you select the right components for your machine. This level of support reduces the risk of errors and ensures your excavator operates efficiently.

How to Locate Authorized Dealers

Finding an authorized Mitsubishi dealer is straightforward. Start by visiting the official Mitsubishi Construction Machinery website, where you can search for dealers in your region. You can also contact Mitsubishi customer service for assistance. When visiting a dealer, ask for proof of authorization to confirm their legitimacy. This step ensures you’re purchasing from a trusted source.

Online Marketplaces

Tips for Avoiding Counterfeit Products

Online marketplaces offer convenience, but you must remain cautious to avoid counterfeit products. Always check the seller’s ratings and reviews before making a purchase. Look for detailed product descriptions and clear images to verify authenticity. Trusted platforms often provide buyer protection policies, which safeguard your investment. Avoid deals that seem too good to be true, as they may indicate low-quality or fake parts.

Popular Platforms for Excavator Parts

Several online platforms specialize in Mitsubishi mini excavator parts.

Alibaba: A leading marketplace offering a wide range of parts, including engine components and hydraulic systems.

TVH: Known for reliable mini excavator engine parts compatible with Mitsubishi models.

These platforms provide extensive options, making it easier to find the parts you need. However, always verify the seller’s credibility before finalizing your purchase.

Local Suppliers

Verifying the Credibility of Local Businesses

When sourcing parts locally, evaluating the supplier’s credibility is crucial.

Check supplier credentials, such as certifications like ISO 9001.

Read customer reviews on platforms like Trustpilot to gauge reliability.

Assess the supplier’s adherence to quality standards and delivery performance.

These steps help you identify trustworthy suppliers who can meet your needs effectively.

Advantages of Working with Local Suppliers

Local suppliers offer several benefits. They provide faster delivery times, reducing downtime for your excavator. You can inspect parts in person, ensuring they meet your quality expectations. Additionally, local businesses often offer personalized service, helping you find the exact parts you need. Building a relationship with a reliable local supplier can streamline future purchases and enhance your overall experience.

️ Pro Tip: Maintain a detailed inventory list of required parts, including part numbers and specifications. This preparation saves time and ensures you’re ready when contacting suppliers.

YNF Machinery: A Trusted Supplier

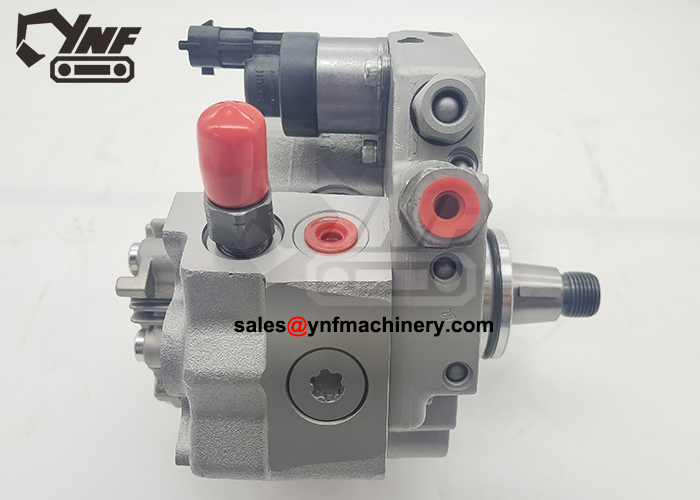

Why Choose YNF Machinery for Excavator Couplings

YNF Machinery stands out as a trusted supplier for excavator couplings. Their couplings are crafted from high-quality materials, ensuring durability and reliable performance. These components are designed to handle heavy-duty applications, making them ideal for demanding work environments. You can rely on YNF Machinery’s couplings to maintain operational efficiency, even under harsh conditions.

The company offers a wide range of coupling types, including Centaflex-A, Centaflex-H, Bowex, and Monolastic. Each type provides unique benefits, such as vibration isolation or high torque capacity. This variety ensures you can find the perfect coupling for your specific excavator model. Additionally, YNF Machinery simplifies the sourcing process with an efficient online catalog. This feature allows you to quickly locate and order the parts you need, minimizing downtime and keeping your operations running smoothly.

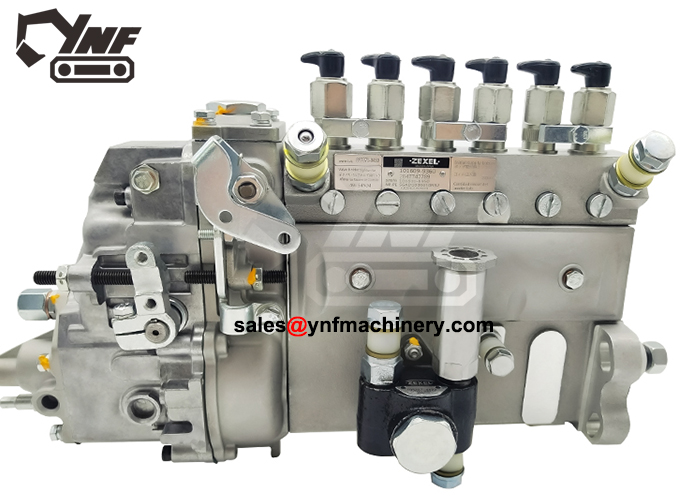

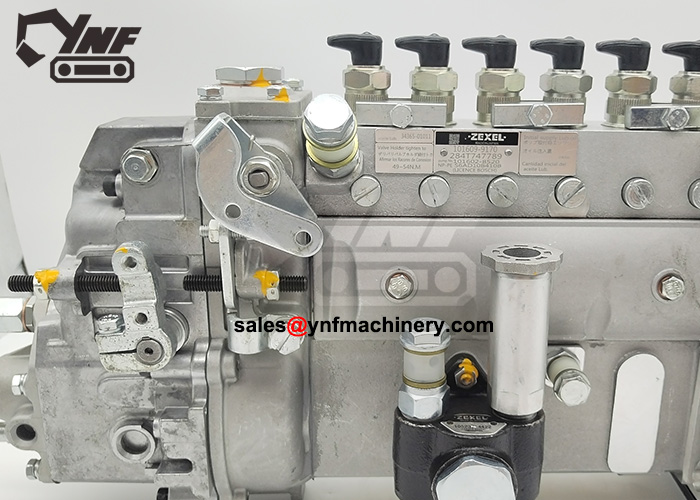

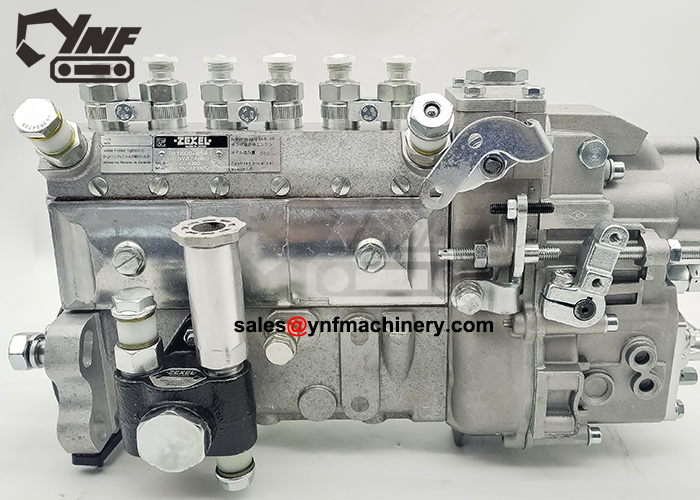

High-Quality Excavator Engine Parts from YNF Machinery

When it comes to excavator engine parts, YNF Machinery delivers exceptional quality. Their engine components, such as pistons, crankshafts, and injectors, are built to withstand high temperatures and pressure. These parts ensure optimal engine performance, reducing fuel consumption and emissions. By choosing YNF Machinery, you invest in parts that enhance the efficiency and longevity of your excavator.

YNF Machinery’s engine parts meet or exceed OEM standards, providing you with reliable options for both OEM and aftermarket needs. The company’s commitment to quality extends to its pricing. They maintain lower production costs without compromising on durability, offering you cost-effective solutions. With a vast dealer network and comprehensive customer support, YNF Machinery ensures you receive the right parts for your excavator. Whether you need couplings or engine components, YNF Machinery remains a dependable choice for mitsubishi mini excavator parts.

️ Pro Tip: Regularly inspect your excavator’s couplings and engine parts to identify wear and tear early. Replacing worn components promptly can prevent costly repairs and extend your machine’s lifespan.

Tips for Evaluating Suppliers

Checking Reviews and Ratings

Importance of Customer Feedback

Customer feedback provides valuable insights into a supplier’s reliability and product quality. Reviews often highlight key aspects such as delivery performance, product durability, and customer service. Positive feedback indicates a supplier’s ability to meet expectations, while negative reviews can reveal potential issues. Look for patterns in reviews to identify consistent strengths or weaknesses. For example, a supplier with frequent praise for on-time delivery likely has strong logistics capabilities.

Where to Find Reliable Reviews

Finding trustworthy reviews requires using credible platforms. Websites like Trustpilot and industry-specific forums offer detailed customer testimonials. These platforms allow you to evaluate a supplier’s reputation based on real experiences. Joining construction industry networks can also help you gather recommendations from peers. Engaging with these resources ensures you make informed decisions when selecting suppliers for mitsubishi mini excavator parts.

Verifying Authenticity

How to Confirm the Legitimacy of a Supplier

Confirming a supplier’s legitimacy protects you from counterfeit products. Start by checking for certifications like ISO 9001, which indicate adherence to quality standards. Request documentation such as quality control reports or performance histories. A legitimate supplier will provide these details without hesitation. Additionally, verify their contact information and business registration to ensure they operate legally.

Red Flags to Watch Out For

Certain warning signs can indicate an unreliable supplier. Be cautious if a supplier avoids sharing certifications or offers vague responses to your inquiries. Poor-quality packaging or inconsistent branding may also signal counterfeit products. Unrealistically low prices often suggest compromised quality. Identifying these red flags early helps you avoid costly mistakes.

Comparing Prices

Balancing Cost with Quality

Balancing cost and quality requires careful evaluation. Conduct a cost-benefit analysis to weigh the potential benefits of a part against its price. Research the market to understand standard pricing for excavator parts. Compare technical specifications and request samples to assess quality firsthand. This approach ensures you invest in parts that align with your operational goals.

Avoiding Deals That Seem Too Good to Be True

Deals that appear too good to be true often come with hidden risks. Low-quality parts may fail prematurely, leading to equipment breakdowns. Overpaying for unsuitable components can also disrupt your operations. Always prioritize suppliers who offer transparent pricing and proven reliability. This strategy minimizes risks and ensures long-term value for your investment.

Tip: Collaborate with industry experts to refine your purchasing strategy. Their insights can help you identify high-quality parts and trustworthy suppliers.

Choosing the right mitsubishi mini excavator parts ensures your equipment performs efficiently and lasts longer. Focus on compatibility, material quality, and reliable suppliers to avoid costly repairs. Keep an inventory of frequently worn parts to minimize downtime. Pay attention to the undercarriage, as it often experiences wear. Create a machine log to track part conditions and plan timely repairs. Avoid rushing purchases or skipping inspections. By prioritizing quality and support, you enhance your excavator’s reliability and functionality, ensuring long-term success in your operations.

️ Pro Tip: Consult experts and research market trends to make informed decisions when purchasing replacement parts.

FAQ

1. How do I know if a part is compatible with my Mitsubishi mini excavator?

Check your excavator’s model number and specifications in the equipment manual. Match these details with the part’s dimensions and requirements. You can also consult a trusted supplier like YNF Machinery for expert guidance.

Tip: Always double-check compatibility to avoid costly installation errors.

2. What is the difference between OEM and aftermarket parts?

OEM parts are made by the original manufacturer and guarantee perfect fit and quality. Aftermarket parts, made by third-party companies, often cost less but require careful evaluation to ensure reliability and compatibility.

️ Pro Tip: Choose aftermarket parts from reputable suppliers to balance cost and performance.

3. How can I extend the lifespan of my excavator parts?

Perform regular maintenance, including cleaning and lubrication. Inspect parts for wear and replace them promptly. Use high-quality components like those from YNF Machinery to reduce stress on your equipment.

Note: A maintenance schedule can help you track part conditions effectively.

4. Why is material quality important when selecting parts?

High-quality materials resist wear and withstand harsh conditions. This durability reduces the frequency of replacements and ensures consistent performance. For example, bronze bushings offer excellent strength and corrosion resistance.

✅ Reminder: Investing in durable materials saves money in the long run.

5. Can I get technical support when buying parts from YNF Machinery?

Yes, YNF Machinery provides comprehensive technical support. Their team assists with part selection, installation guidance, and troubleshooting. This service ensures you get the right parts and maintain smooth operations.

Contact: Reach out to YNF Machinery via email or WhatsApp for expert assistance.