Part number: LS30P01063F1

Product name: COUPLING ASSEMBLY

Brand name: YNF®

Models: KOBELCO PARTS SK485-8 SK480-8 SK460-8 SK500HDLC-8 EXCAVATORS

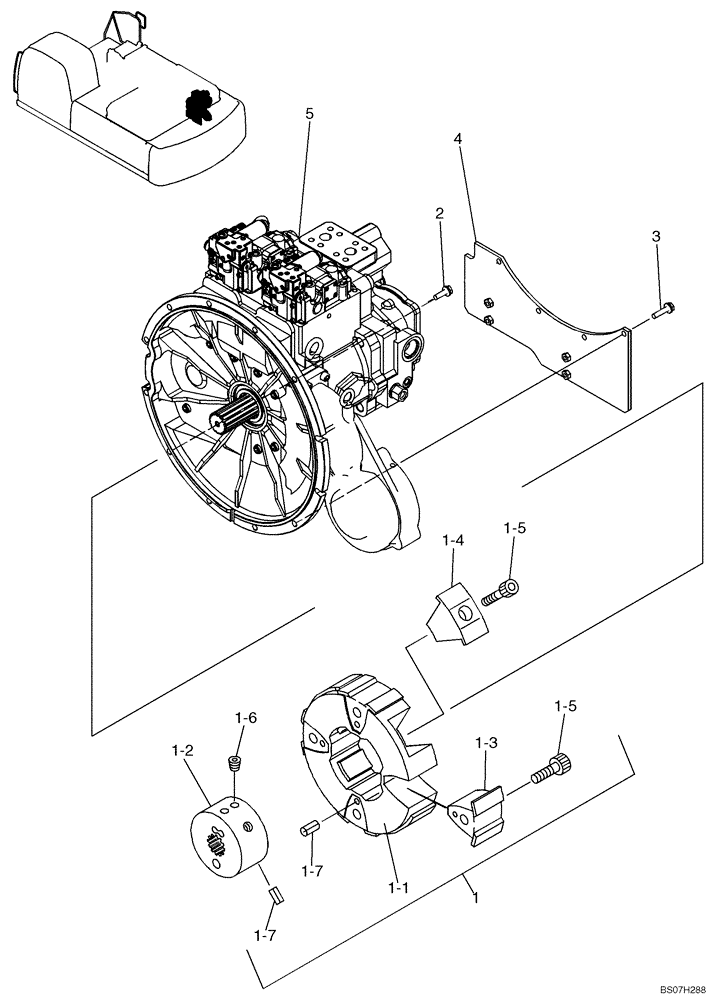

Drawing:

| Pos. | Part No | Qty | Parts name | Comments |

|---|---|---|---|---|

| 1. | LS30P01063F1 | [1] | COUPLING | KOB Assembly |

| 1-1. | NA | [1] | NOT SERVICED | FOR Rubber |

| 1-2. | NA | [1] | NOT SERVICED | FOR Hub |

| 1-3. | NA | [4] | NOT SERVICED | FOR Insert |

| 1-4. | NA | [4] | NOT SERVICED | FOR Insert |

| 1-5. | NA | [8] | NOT SERVICED | FOR Screw, Cap |

| 1-6. | NA | [2] | NOT SERVICED | FOR Screw, Set |

| 1-7. | NA | [12] | NOT SERVICED | FOR Pin, Spring |

| 2. | ZM73C10035 | [8] | BOLT,M10x35mm – Course Thread | KOB M10x1.50x35mm (Incls. Washer) |

| 3. | ZM73C10045 | [4] | BOLT,M10x45mm – Course Thread | KOB M10x1.50x45mm (Incls. Washer) |

| 4. | LS30H01179P1 | [1] | BRACKET | KOB , Serial Range: -YS07U0792 |

| 4. | LS02P00086F1 | [1] | ENGINE ASSEMBLY | KOB , Start Serial: YS07U0793 |

| 5. | LS10V00016F1 | [1] | PUMP | KOB Standard Hydraulic Pump Assembly, See Figure 08-30 Superseded by part number: LS10V00016F6 |

| 5. | LS10V00016F1R | [1] | REMAN-HYD PUMP | BRR For SK485-8 Acera Mark 8 |

| 5. | LS10V00016F1C | [1] | CORE-HYDRAULIC PUMP | BRR Return Number |

What’s excavator hydraulic pump couplings?

An excavator hydraulic pump coupling is a mechanical device that connects the hydraulic pump to the engine of an excavator. It is an essential component of the excavator’s hydraulic system and plays a critical role in the efficient and reliable operation of the machine.

The hydraulic system of an excavator is responsible for powering the various components of the machine such as the boom, arm, and bucket. The system relies on a hydraulic pump to generate the pressure required to move the hydraulic fluid that powers these components. The hydraulic pump is typically driven by the engine of the excavator, and this is where the hydraulic pump coupling comes in.

The coupling is designed to connect the hydraulic pump to the engine and transfer power from the engine to the hydraulic pump. It is typically made of high-strength materials such as steel or aluminum and is designed to withstand high torque and rotational speeds.

There are several different types of hydraulic pump couplings available, each with its own unique design and features. One common type is the flexible coupling, which is designed to compensate for misalignment between the engine and hydraulic pump. This type of coupling consists of two flanges that are connected by a flexible element such as a rubber or metal disc. The flexible element allows for some degree of misalignment between the engine and hydraulic pump, which helps to reduce wear and tear on both components.

Another type of hydraulic pump coupling is the rigid coupling, which is designed to provide a more direct connection between the engine and hydraulic pump. This type of coupling consists of two flanges that are bolted together, providing a solid connection between the two components. Rigid couplings are generally more durable than flexible couplings but are less forgiving when it comes to misalignment.

In addition to flexible and rigid couplings, there are also other types of couplings available, such as gear couplings and chain couplings. Gear couplings use gears to transfer power between the engine and hydraulic pump, while chain couplings use chains to transmit power.

When selecting a hydraulic pump coupling for an excavator, it is important to consider several factors such as the power requirements of the hydraulic system, the size and weight of the components being driven, and the operating conditions of the machine. It is also important to ensure that the coupling is properly installed and maintained to ensure optimal performance and reliability.

In conclusion, an excavator hydraulic pump coupling is a critical component of an excavator’s hydraulic system. It connects the hydraulic pump to the engine and transfers power from the engine to the hydraulic system that drives the machine’s various components. There are several different types of couplings available, each with its own unique design and features. When selecting a coupling for an excavator, it is important to consider several factors such as power requirements, component size and weight, and operating conditions. Proper installation and maintenance of the coupling are also essential for optimal performance and reliability.