Complete Guide to Hydraulic Pump Spline Shaft Hub Sizes

Hydraulic pump spline shaft hubs link pumps to other parts. These hubs move power smoothly, keeping things running well. A good fit between the hub and shaft stops misalignment. This helps reduce damage and wear over time. Picking the right size and type makes your equipment last longer. The correct hub also saves money by avoiding repairs and delays. Strong hubs are important for keeping your hydraulic system working properly.

Understanding Hydraulic Pump Spline Shaft Hub Sizes

What Defines a Hydraulic Pump Spline Shaft Hub?

A hydraulic pump spline shaft hub connects the pump to other parts. It transfers power smoothly by holding the shaft tightly. This keeps everything aligned and working well. The hub has splines, which are grooves or teeth that fit together with the shaft. These grooves stop slipping and help transfer torque efficiently.

The hub’s design depends on what the system needs. Some hubs are straight, while others are curved, called involute. Each type works for specific systems. Picking the right hub improves performance and reduces wear on parts like wheels and moving components.

Key Dimensions and Measurements to Know

To choose the right hub, you need to know its size. These measurements show how well the hub fits and works. Here are some important dimensions:

| Measurement Aspect | Details |

|---|---|

| Pitch Diameter | Based on spline number and depth. |

| Spline Compliance Check | Checked using pins in the male part’s tooth space. |

| Overwire Dimensions | Includes minor and major diameters, plus pressure angle. |

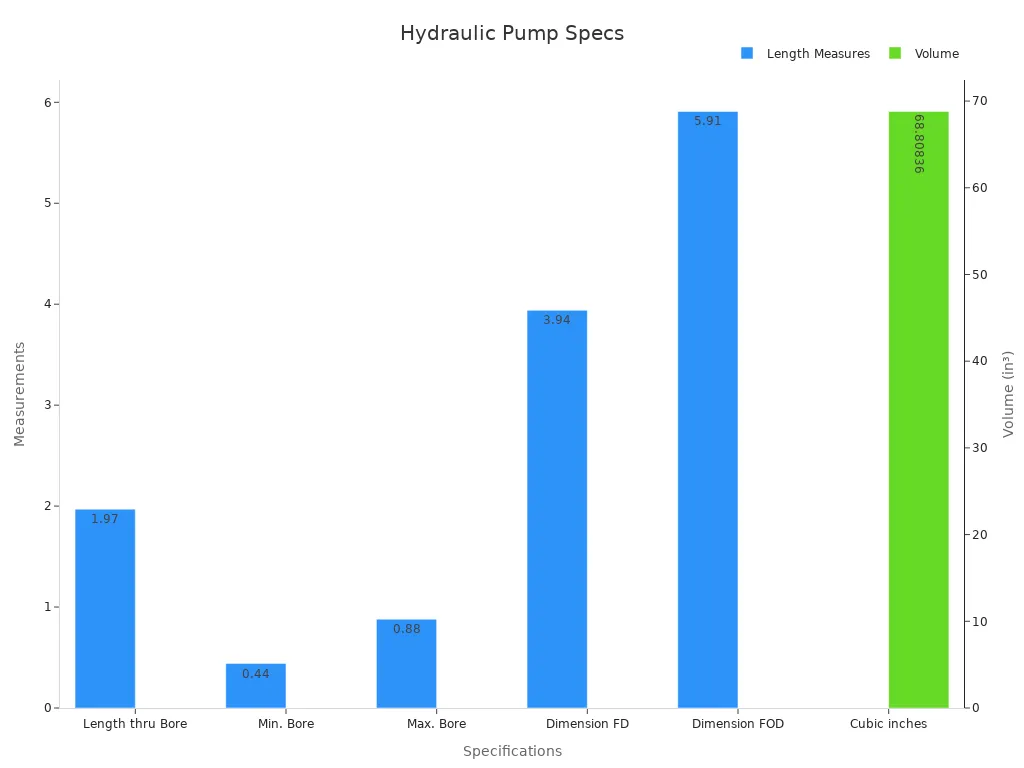

Standards like ANSI B92.1A (SAE J744) and DIN5480 guide hub sizes. These rules make sure hubs work with different systems. Below is a table of common hub specifications:

| Specification | Value |

|---|---|

| Length thru Bore | 1.970 in (28.00 mm) |

| Min. Bore | 0.440 in (10.00 mm) |

| Max. Bore | 0.880 in (26.00 mm) |

| Dimension FD | 3.940 in (100.08 mm) |

| Dimension FOD | 5.910 in |

| Cubic inches | 68.80836 in³ |

These exact sizes help the hub fit perfectly. This lowers the chance of misalignment and boosts system efficiency.

Why Proper Fit and Alignment Matter

A good fit and alignment are key for hydraulic systems. A well-fitted hub holds the shaft securely. This stops damage to the coupling and other parts. Misalignment can cause more wear, less efficiency, and even system failure.

For instance, a double-cardanic steel disk coupling reduces restoring forces. This lowers wear on motor and pump bearings, making them last longer. Flexible couplings also help by handling misalignments without losing performance. These features keep the system efficient and cut maintenance costs.

Every part in a hydraulic system works together for smooth operation. The hub helps keep everything aligned. Choosing the right hub size and type improves system performance and avoids expensive repairs.

Factors Influencing Hub Size Selection

Matching Hydraulic System Requirements

Choosing the right hub size starts with knowing your system’s needs. Each hydraulic system has specific requirements like operating pressure, flow rate, and power. The hub must match these to keep the system working well. If the hub doesn’t fit, it can cause problems or even break the system.

Think about the type of machine you’re using. For example, excavators need hubs that handle heavy loads and high torque. Smaller machines, like farm equipment, need lighter hubs. Always check your system’s manual to find the recommended hub size and type.

Tip: Write down your system’s details. This helps you pick the right parts when replacements are needed.

Torque, Load, and Performance Considerations

Torque and load are important when picking a hub. The hub must move torque without slipping or wearing out. A hub that’s too small can break under pressure. A hub that’s too big can cost more and add weight.

A good hub spreads force evenly. This lowers stress on the shaft and other parts. It also makes the system work better. Think about conditions like heat and vibration, as they can affect the hub’s performance.

Note: Pick a hub that handles more torque than your system needs. This gives extra safety and makes the hub last longer.

YNF03710

9 Teeth Spline Hub OD60 ID12-15.6 H36 Z3 10mm

YNF01422

10 Teeth Coupling Spline Hub OD60 ID14.5-18 H36 Z3 Bolt 10mm

YNF01640

11 Teeth Coupling Spline Hub OD60 ID19-16.2 H36 Z3 Bolt 10mm

YNF03413

13 Teeth Coupling Spline Hub OD60 ID19-22 H36 Z3 Bolt 10mm

YNF03718

14 Teeth Coupling Spline Hub OD60 ID27.3-31.2 H36 Z3 Bolt 10mm

YNF03734

10 Teeth Coupling Spline Hub OD70 ID14.5-18 H43 Z3 Bolt 12mm

YNF02947

11 Teeth Coupling Spline Hub OD70 ID16-19 H46 Z3 Bolt 12mm

YNF02946

13 Teeth Coupling Spline Hub OD70 ID19-22 H46 Z4 Bolt 12mm

YNF01880

13 Teeth Coupling Spline Hub OD70 ID19-22 H50 Z3 Bolt 12mm

YNF01206

15 Teeth Coupling Spline Hub OD70 ID22-26 H37 Z3 Bolt 12mm

YNF14540

Flat Key Hub ID30 OD70 H50

YNF15730

OD70-14T ID28-32 OD70 H46 Z3

YNF14677

OD70-15T ID22 26 OD70 H46 Z4 M12

YNF02930

OD85-12T ID30-35 H45 Z4

YNF01882

OD85-13T ID19-22 H45 Z3 14mm

YNF00891

OD85-14T ID27-31 H45 14T Z3

YNF01641

OD85-14T 35-40 14T

YNF03761

OD85-14T H43 27-31 Z4 16mm

YNF15254

OD85-14T Customized ID27 31 H60 Z3

YNF02450

OD85-15T ID22-26 H45 Z3 14mm

YNF01474

OD85-15T ID36-42 H44 Z4 16mm

YNF03567

OD85-16T ID40-45 H42 Z4 14mm

YNF01213

OD85-16T ID40-45 H42 16mm

YNF03545

OD85-17T ID28-31 H42 Z3 14mm

YNF02121

OD85-17T ID28-31 H42 Z4

YNF02697

OD85-17T ID42-47 H45 Z4 16mm

YNF13961

ID42.5mm Keyed (12mm key way) OD85mm H55mm

YNF15777

14T ID28-32 OD85 H55 M14 Z3

YNF15843

OD85-17T ID34-37.8 OD85 H45 Z4 M16

YNF16063

OD125 12T ID30.5-35.5 H61.5 Z4 M20

YNF01643

OD125 14T ID35-40 H62 Z4 20mm

YNF02451

OD125 15T ID44-50 H78 Z4 20mm

YNF01476

OD125 15T ID44-51 H62 Z4 20mm

YNF00846

OD125 17T ID42-47 H62 Z4 20mm

YNF02453

OD125 22T ID44-49 H53 Z4 20mm

YNF16365

OD125 24T ID46-50.7 H70.7

YNF02591

OD125 24T ID46-51 H62 Z4 20mm

YNF12913

OD125 27T ID41.5-45 H80 Z4 M20

YNF14562

OD125 31T ID61-65.5 H70 Z4 M20mm

YNF14848

OD125 Flat Key Hub ID53.75 W12 H85 Z4 M20 Customization

YNF15514

ID65 Flat Key Hub OD125 H80 M20 Customization

YNF01479

OD160 15T ID45-52 H60 Z4 20mm

YNF03549

OD160 17T ID42-47 H60 Z4 20mm

YNF12694

OD160 24T ID46-51 OD160 H70

YNF03821

OD160 31T ID60-65 H70 Z4 20mm

Factors Influencing Hub Size Selection

Material Strength and Durability

The hub’s material affects how strong and long-lasting it is. Strong materials handle heavy loads and resist wear. Carbon steel 1045 works well for general use. Alloy steels like 4140 or 4340 are better for tough jobs or critical systems.

| Material Type | Tensile Strength (MPa) | Best Uses |

|---|---|---|

| Carbon Steel 1045 | 570-700 | Everyday use |

| Alloy Steel 4140 | 850-1000 | Heavy-duty tasks |

| Alloy Steel 4340 | 980-1100 | Important applications |

Think about where the hub will be used. Harsh environments may need special coatings or materials. Picking the right material makes the hub last longer and work better.

Tip: Ask manufacturers which material fits your needs. This helps you avoid mistakes and make smart choices.

Exploring Common Hub Configurations

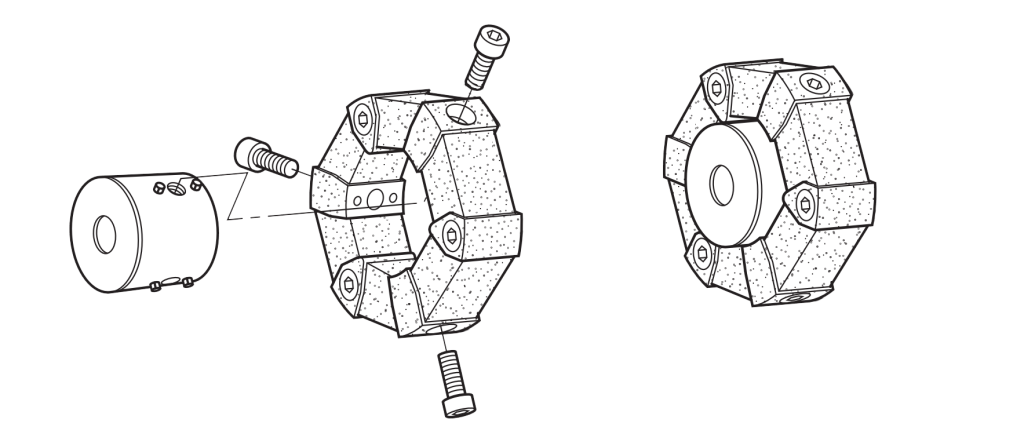

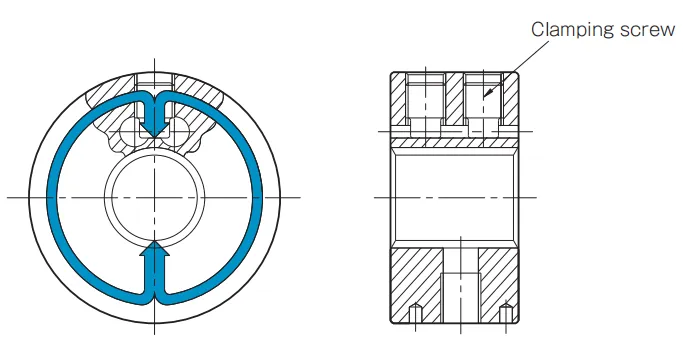

Coupling a pump shaft (spline shaft) to a cylindrical hub

A clamping hub that completely locks a cylindrical hub to a spline shaft using CENTA-LOCK action.

Straight Spline Shaft Hub Configurations

Straight spline shaft hubs are very common in hydraulic systems. These hubs have straight splines that run along the shaft’s length. This design helps the hub fit tightly with the shaft. It ensures smooth torque transfer and reduces alignment problems.

Straight spline hubs are simple and easy to use. They are cheaper to make and maintain, making them a good choice. However, they work best for systems with medium torque and load needs. For extreme conditions, other hub types may be better.

Tip: Count the splines and check their size to match your shaft.

Involute Spline Shaft Hub Configurations

Involute spline hubs have curved splines instead of straight ones. The curved shape spreads force evenly across the teeth. This lowers wear and makes them great for high torque or heavy loads.

Involute hubs can handle small misalignments without losing performance. This makes them useful for tough jobs like construction or factory machines.

Note: Look at the pressure angle and tooth shape when choosing an involute hub. These details affect how well it works and lasts.

Custom and Specialized Hub Configurations

Standard hubs don’t always fit every system. Custom hubs are made for special needs like odd shaft sizes or high torque demands.

Custom hubs may have stronger materials, special coatings, or unique spline designs. These features improve performance and make the system last longer. Some companies, like YNF Machinery, offer custom hubs to fit perfectly.

Reminder: Share your system’s details with the manufacturer to design the right hub.

Practical Tips for Picking the Right Hub Size

Checking System Needs and Specifications

Understand what your hydraulic system needs first. Each system has unique specs like operating pressure, flow rate, and torque. These details help you find the right hub. Systems with high torque need hubs that handle heavy loads without slipping.

Think about the machine’s job and environment. Excavators need hubs that resist strong pressure and vibrations. Smaller machines, like farm tools, work better with lighter hubs. Always check your system’s manual for the suggested hub size and type.

Tip: Make a list of your system’s specs. Include shaft size, torque limits, and working conditions. This helps you pick the right hub without missing anything important.

Using Manufacturer Advice and Standards

Manufacturers give helpful tips for choosing the best hub. They share details like sizes, materials, and compatibility. Standards like ANSI B92.1A or DIN5480 ensure hubs fit different systems well. This lowers the chance of misalignment or poor performance.

Ask manufacturers for advice. Companies like YNF Machinery make hubs for specific needs. They can suggest hubs that improve strength and efficiency, whether you need a front hub, rear hub, or special designs like freewheel hubs.

Note: Follow the manufacturer’s instructions when installing the hub. Proper alignment and tight fitting protect parts and make your system last longer.

Avoiding Hub Selection Errors

Picking the wrong hub can cause expensive fixes and delays. A common mistake is choosing a hub just because it’s cheap. While cost matters, focus on quality and compatibility to avoid problems. Another error is ignoring torque and load needs. A small hub might break, while a big hub adds extra weight.

Look at the hub’s material and design. For example, freecoaster hubs and long-lasting wheel packages work well for tough systems. Skipping these details can lead to frequent repairs and lower performance.

Reminder: Test the hub’s fit and alignment before deciding. This step ensures the hub works properly and reduces wear on wheels and other parts.

Consequences of Choosing the Wrong Hub Size or Configuration

Performance Problems and System Breakdowns

Picking the wrong hub size can hurt your system’s performance. A bad hub won’t transfer torque properly, causing uneven force. This makes your equipment slower and less powerful. For example, if a freewheel hub doesn’t match the shaft, torque becomes uneven. Over time, this can break your system, stopping it from working.

Wrong hubs also affect wheel systems. If the hub doesn’t fit the wheel, it strains other parts. This strain can cause breakdowns, especially in systems under high pressure. To avoid these problems, always check your hub fits your system.

Faster Wear and Higher Costs

Using the wrong hub wears out your equipment faster. Misaligned hubs rub against parts, damaging shafts and wheels. This means you’ll need repairs more often, costing you money. For example, a mismatched bmx hub can wear out quickly, needing early replacement.

Bad hub choices also increase maintenance costs. Uneven force from the hub puts extra stress on wheel systems. This stress makes parts wear out sooner, shortening their lifespan. You’ll need regular fixes, which adds to your expenses.

Safety Risks and Lost Time

Wrong hub setups can be dangerous. A loose hub might cause the wheel to fall off or stop working. This can lead to accidents for workers nearby. For example, a freecoaster hub that fails under heavy loads can cause harm.

System downtime is another problem. If your equipment breaks because of a bad hub, work stops. Fixing and replacing parts takes time, delaying your projects. To avoid these issues, pick hubs made for your system’s needs.

Tip: Ask manufacturers for help choosing the right hub. This keeps your system safe and running smoothly.

The Role of High-Quality Hubs in System Longevity

Benefits of Precision-Engineered Hydraulic Pump Spline Shaft Hubs

Precision-made hubs help your equipment last longer. These hubs fit perfectly with the shaft, stopping misalignment and wear. A good hub lowers friction, protecting important parts like shafts and wheels. It also improves torque transfer, making your system work better.

Strong hubs handle heavy loads and tough conditions. They resist damage from vibrations and pressure, keeping performance steady. Choosing precision hubs means less maintenance and fewer repairs. This saves money and keeps your equipment running well for years.

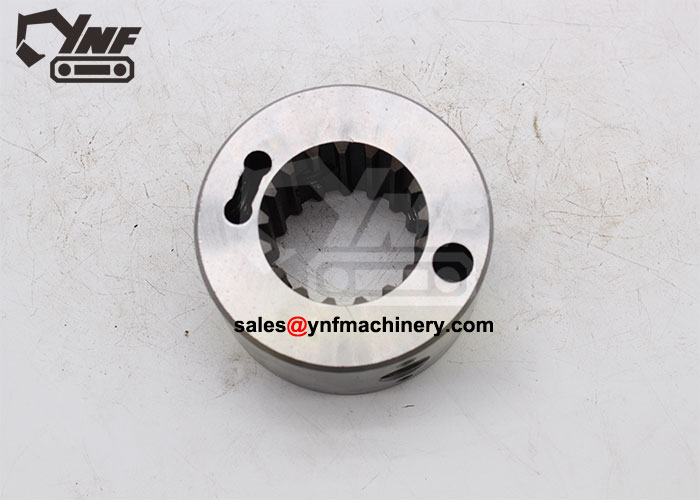

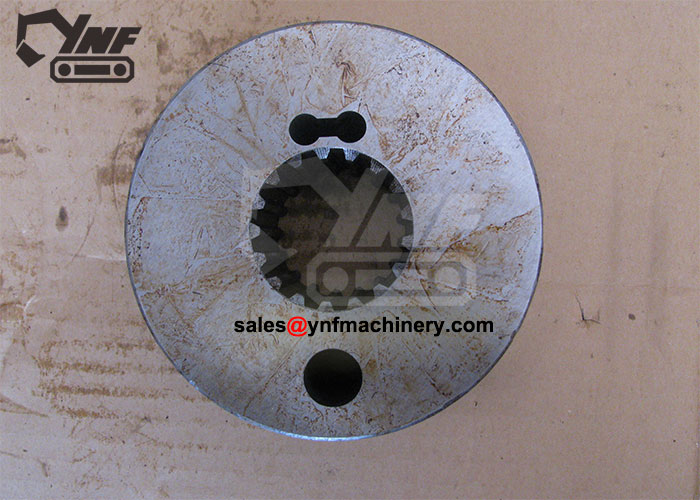

How YNF Machinery’s Spline Hubs Enhance Excavator Performance

YNF Machinery’s hubs improve how excavators work. These hubs are carefully made to transfer torque and stay aligned. Their small size fits well with different wheel systems. This spreads force evenly and reduces stress on parts.

YNF hubs are tough and built for hard jobs. They don’t wear out easily, even in rough conditions. This means fewer breakdowns and longer equipment life. With YNF hubs, your excavators will work smoothly and get more done.

Customization Options for Unique System Requirements

Not all systems can use standard hubs. Custom hubs are made to fit special needs. You can pick the size, material, and spline design that works best. For example, custom hubs are great for high torque or unusual setups.

YNF Machinery offers many custom options to fit your system. Their team helps design hubs that match your needs exactly. This gives a better fit, improved performance, and longer-lasting equipment. Custom hubs are a smart way to boost efficiency and reduce downtime.

Picking the right hydraulic pump hub keeps your system working well. A good fit lowers wear, boosts performance, and cuts down on repairs. Strong, well-made hubs transfer torque better and last longer. They are a great choice for your equipment.

For help and trusted advice, talk to experts like YNF Machinery. They offer custom solutions to match your system’s needs. This ensures your equipment works its best and stays reliable for a long time.

FAQ

A hydraulic pump spline shaft hub links the pump to other parts. It helps transfer torque smoothly and keeps everything aligned. This lowers wear and tear on the system. Choosing the right hub makes your equipment work better and last longer.

To measure a spline shaft hub, check its pitch diameter, spline count, and length. Use calipers for accurate measurements. Follow standards like ANSI B92.1A or DIN5480 to ensure it fits your system.

Tip: Double-check your measurements to prevent alignment problems.

No, not all systems can use standard hubs. Each system has specific needs like torque, load, and shaft size. For special setups, custom hubs might be required.

Reminder: Check your system manual or ask the manufacturer for advice.

Carbon steel 1045 and alloy steels 4140 or 4340 are great choices. Carbon steel is good for general use. Alloy steels are better for heavy loads and tough conditions. Pick a material based on your system’s needs and environment.

To avoid errors, match the hub to your system’s torque and load needs. Make sure the size and material are compatible. Don’t pick a hub just because it’s cheap. A bad hub can cause more repairs and delays.

Note: Follow manufacturer advice to choose the right hub.

■ Materials

If the material is not strong enough on the flywheel side, it can be compensated for by changing the bolt length. YNF Machinery is always using the best material to provide the cylindrical hub.

Hub type: Cylindrical hub Material: S 45 C Tensile strength: 569 N/mm2 or higher

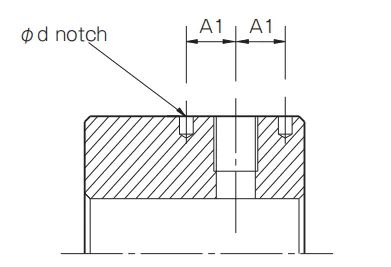

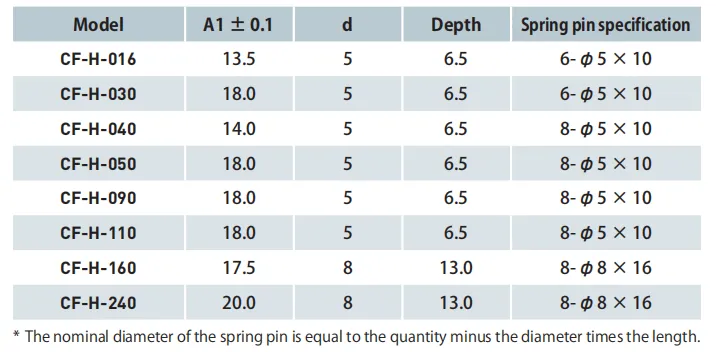

■ Spring pin bore dimensions

All sizes of spring pins are available. Our products perfectly meet your machine’s needs.

There are two ways to categorize the spline hubs, one is by the outer diameter, and the other is by the inner teeth.

YNF Machinery provides spline hubs with 60mm outer diameter to 160 mm outer diameter. Also, we provide the hubs from 0 teeth hubs (key-way hub) to 27 teeth hubs.

Moreover, we also have the ability to produce the hubs according to your requirement. We provide customized service for our customers.

There are 4 steps to confirm the spline hub that you need:

- Measure the outer diameter. To categorize a hub by the outer diameter is a good way. So it’s easy to confirm it by its outer diameter. There are 60 mm outer diameter, 70 mm outer diameter, 85 mm outer diameter, 100 mm OD, 125 mm OD, and 160 mm OD.

- The second step is to count the inner teeth. Because the inner teeth of the spline hub are connected to the pump shaft, you can also count the teeth of the pump shaft. So far, we have developed the following teeth types: 0 teeth, 9 teeth, 10 teeth, 11 teeth, 12 teeth, 13 teeth, 14 teeth, 15 teeth, 16 teeth, 17 teeth, 21 teeth, 22 teeth, 24 teeth, 27 teeth.

- The third step is to measure the inner diameter. Our spline hubs meet different standards which areJIS D2001, SAE J498b and ANSI B92.1. So it’s easy to find the hubs that you need for your machine. If you don’t know what standard of the hub you need, you can just send us the measurement of the hub. We’ll confirm it for you.

- The last step is to check the height of the hub. If you have the old hub at hand, just measure your old hub. Or you can check your pump. The hub is usually slightly shorter than the pump shaft making sure there’s enough room.

There are two kinds of customization ways.

In one situation, you have the old hubs in your hand. In this situation, you can send us the photos and dimensions of the hub to our staff. We’ll confirm the correct hub for you. If we don’t have the hub in stock, we’ll confirm if we have the teeth mold, and we can make it based on our mold. Or you’ll have to send the sample to us.

The second situation is that you only have the drawing. In this case, you can send us the drawing of the hub to our staff and our staff will confirm the details with you.

No, sorry.

Currently, the material of the spline hubs we produce is S45S which is the most suitable material. Because we are producing it in bulk, with scale production, we can order the material at a lower cost. If producing with other materials, the cost will be much higher causing the product price high.

The spline hubs fit the Centaflex-A couplings and Centaflex-H couplings.